Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

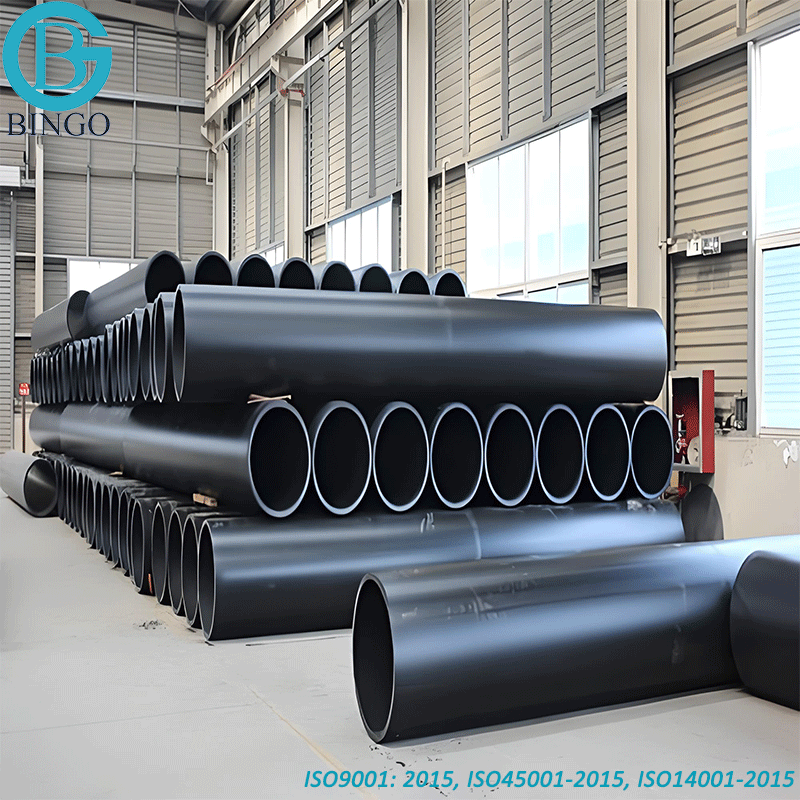

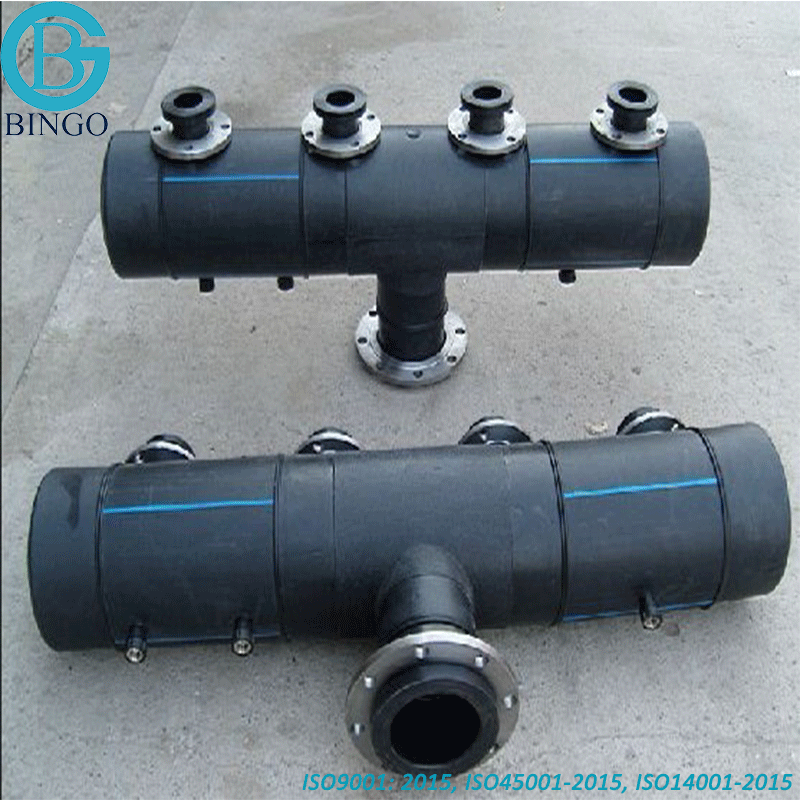

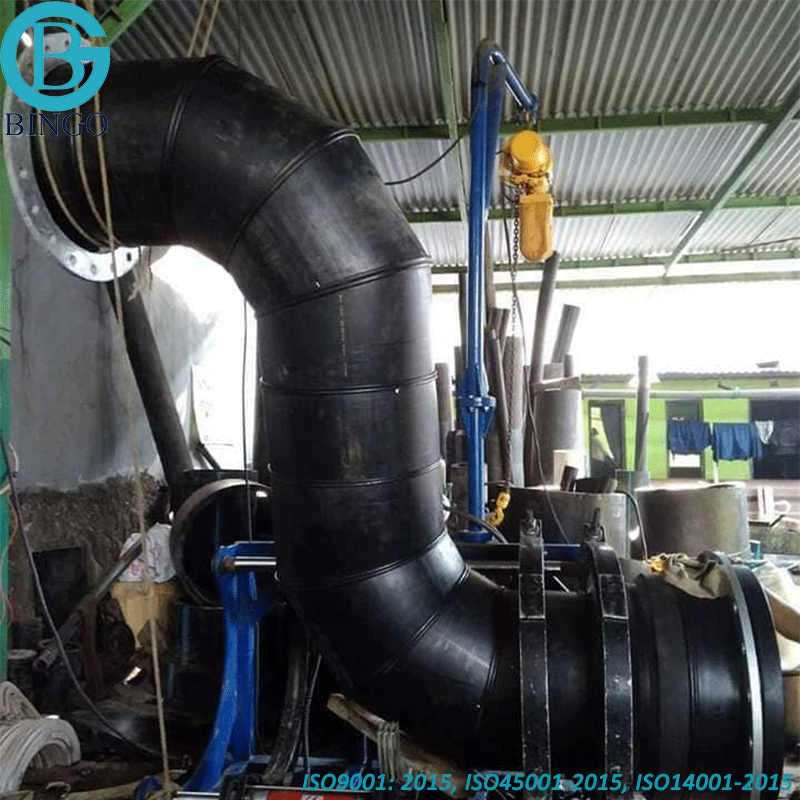

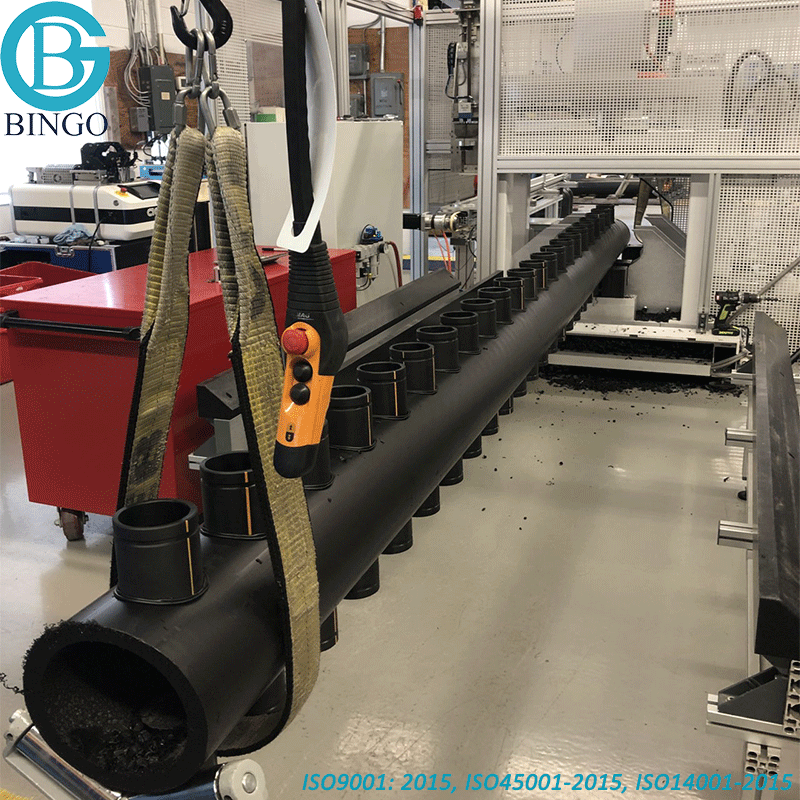

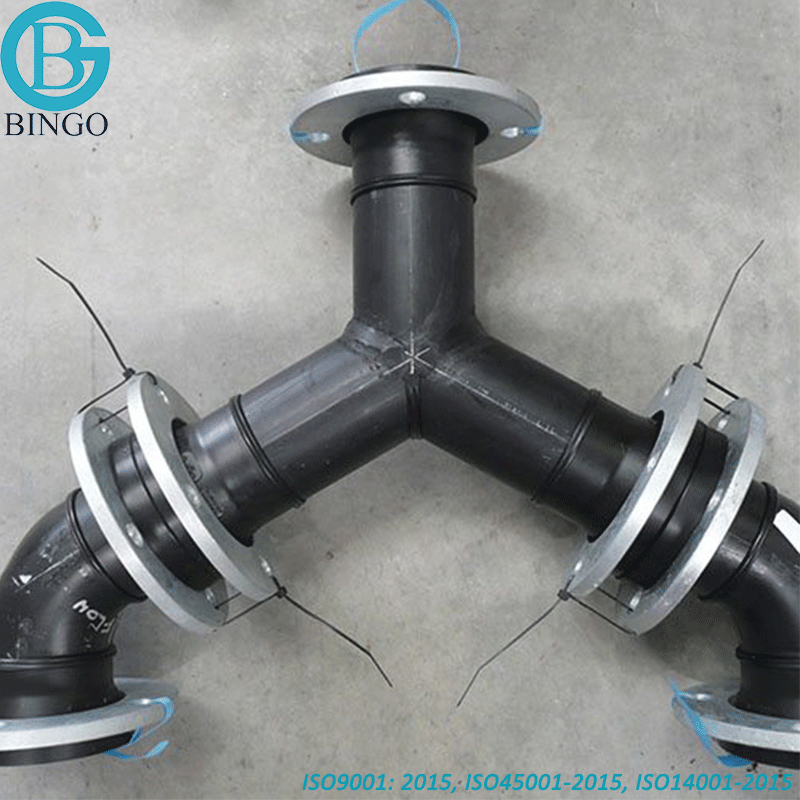

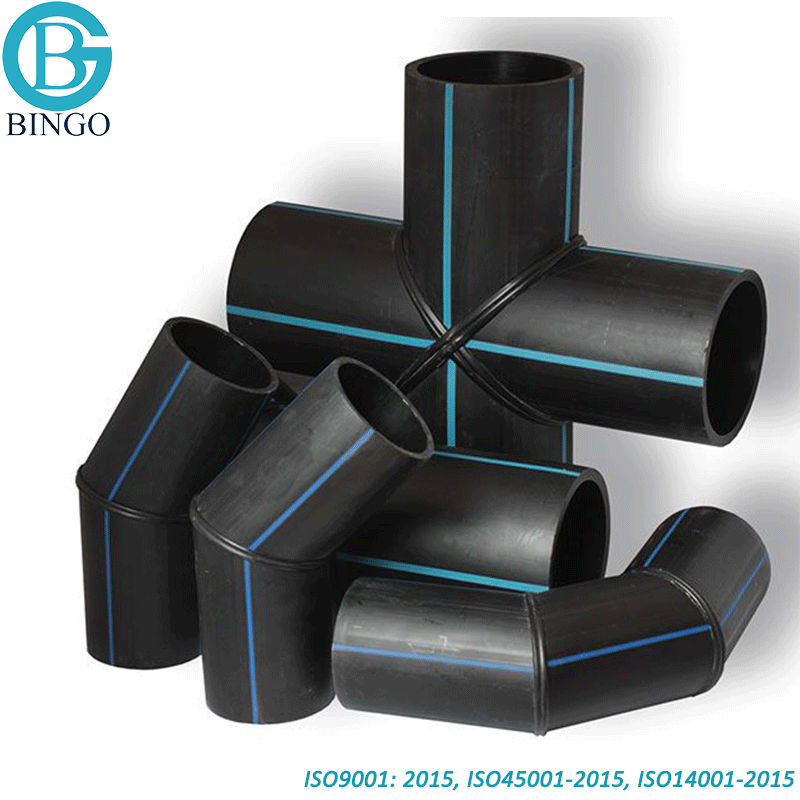

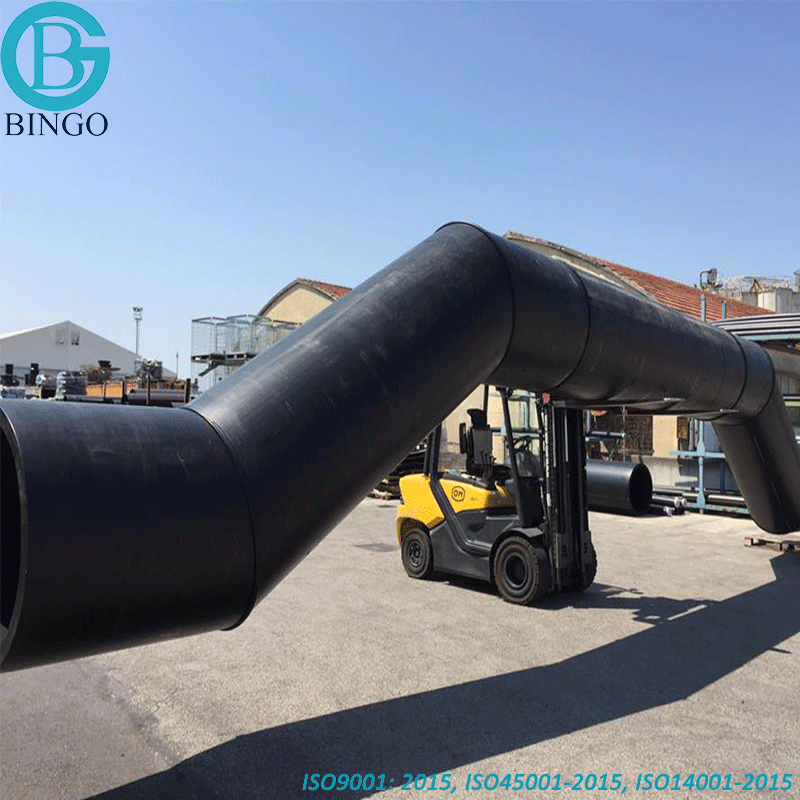

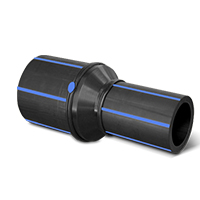

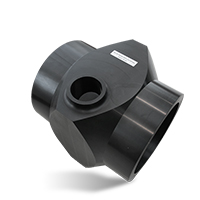

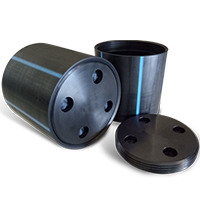

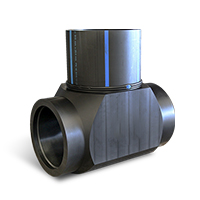

HDPE Fabricated Segments Fitting

Fabricated fittings are constructed by joining sections of pipe, machined blocks, or molded fittings together to produce the desired configuration.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: Packaged by cartons or bags

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) fabricated segments fitting

| Products details information | |

| Product name | High Density Polyethylene (HDPE) fabricated segments fitting |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN110-1400mm(4 inch- 56 inch) |

| Pressure Class | from PN10 to PN25 |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | HDPE Fittings for water, oil and gas, mining, marine, drainage, chemincal, Irrigation, fire fighting... |

| Color | Black or Blue |

| Category | HDPE Fabricated fittings, sweep bend, tee, elbow, reducer tee, cross... |

| Matching products | HDPE pipe fittings, Customized PE fittings, DI/ Steel backing ring flanges, Valves, water meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) fabricated segments fitting

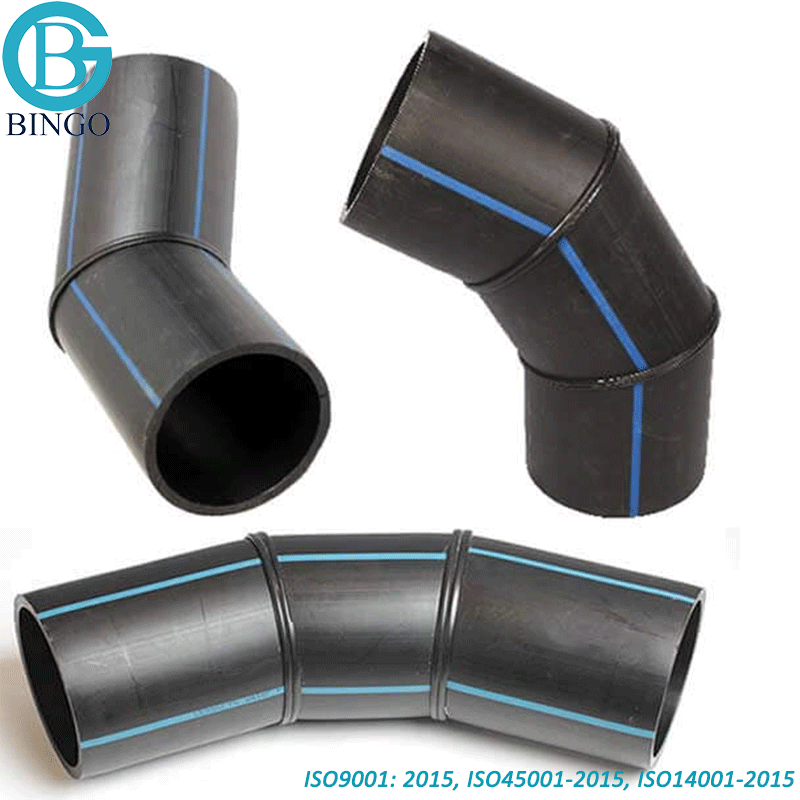

We are able to custom fabricate fittings such as stub ends and elbows to match nonstandard sizes and other diameters such as inches for mating to other pipeline materials.

Components can be joined by butt or socket heat fusion, electrofusion, hot gas welding or extrusion welding techniques. It is not recommended to use either hot gas or extrusion welding for pressure service fittings since the resultant joint strength is significantly less than that of the other heat fusion joining methods.

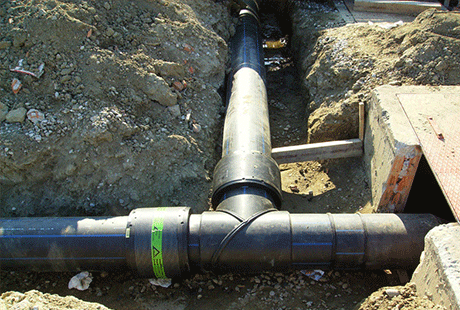

Fabricates segments PE fittings are made by the HDPE pipes according to international standards DIN 16963 or other specifications to meet the specific demands of the customer. Fabricated fittings are suitable for butt-fusion and electro- fusion joints, and it could be connected by the flanges.

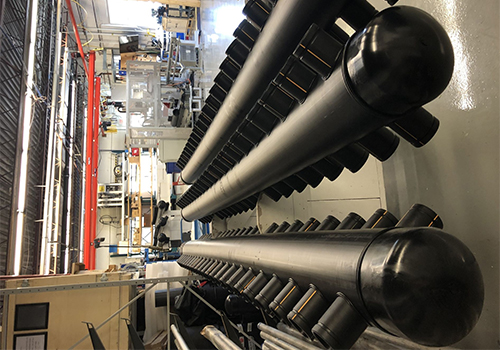

We not only provide the related injection molded fittings such as electro-fusion fittings, butt fusion fittings and saddles, mechanical fittings to provide a complete guaranteed system. But also supply a series of fabricate PE fittings are from 50mm to 1400mm. Specially configured fittings are also manufactured according to the customers requirement. A rigorous test program ensures consistent quality for our fabricated fittings.

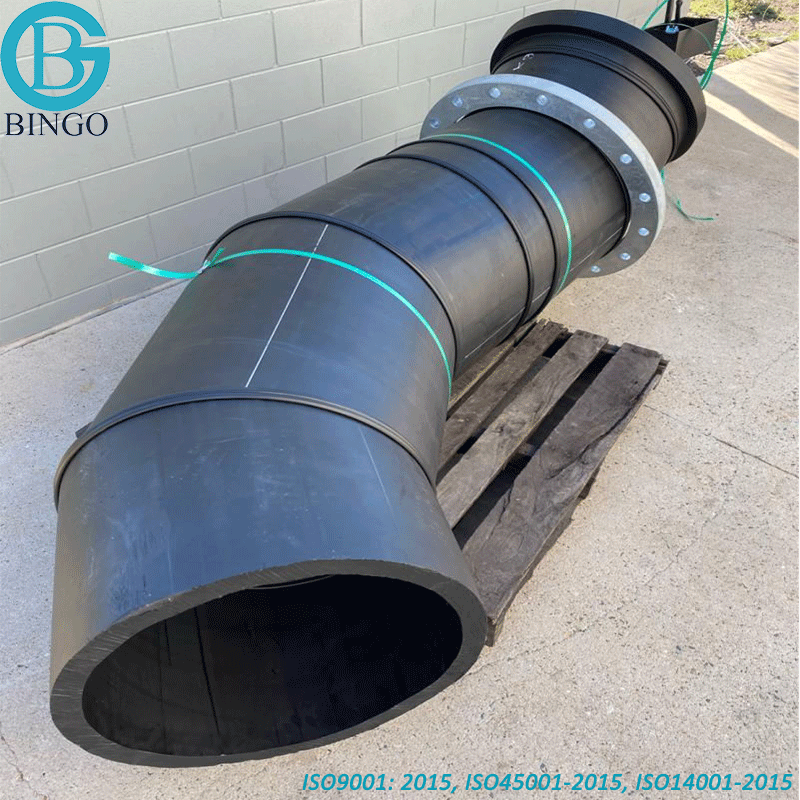

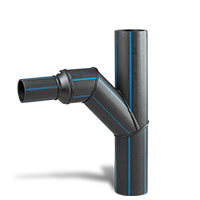

Our fabricated HDPE fittings include fabricated elbows by short radius with 45 deg, 30deg, 60 deg 90 deg, 22.5, deg, 11.25 deg elbows and other customized non-traditional angles (degree elbows) as clients’ requirement, fabricated tees, fabricated reducing tees, fabricated sweep bends by R1.5D, R3D, lateral 45 deg tees, and other fabricated fittings as requirements. All these fabricated fittings are produced and test in accordance with the ASTM 2206-“Standard Specification for Fabricated Fittings of Butt-Fused Polyethylene Plastic Pipe.”

Fabricated fittings designed for full pressure service are joined by heat fusion and must be designed with additional material in regions of sharp geometrical changes, regions that are subject to high localized stress.

Very large diameter fittings require special handling during shipping, unloading, and installation. Precautions should be taken to prevent bending moments that could stress the fitting during these periods. Consult the fittings manufacturer for specifics. These fittings are sometimes wrapped with a reinforcement material, such as fiberglass, for protection.

We are able to manufacture segmented and customized polyethylene fittings in our in-house fabrication facility. Utilizing our high quality pipes and skilled fabrication team you can be assured of a perfect solution to your requirement.

Advantages of High Density Polyethylene (HDPE) fabricated segments fitting

No more cracked pipes (HDPE piping is semi rigid, without being brittle, and thus resists cracking).

Clean welding (no concrete, no messy smelly glues, no welding fumes, no hot flames)

High durability

Can be used for a diverse range of applications

Available in a wide range of thicknesses and pressure ratings

Non-corrosive, chemical resistant

Light weight for easier and more cost effective freight, handling and installation

Specification of High Density Polyethylene (HDPE) fabricated segments fitting

| Item | Fittings Types | Specified Fittings | Diameter(mm) | Pressure Rates(PN-Bar) | Manufacturing Process |

| 6 | Fabricated Segments Fittings-Butt Fusion Ends | Elbow: 11.25 Deg,22.5Deg 30Deg,45Deg 60Deg,90Deg and other required degrees | DN110-1200mm | PN16, PN12.5, PN10, PN8 | Segmented Fabrication |

| Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Reducer Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Lateral Tee(45 deg Tee) | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Cross Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Reducer Cross Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Special-shaped S tube, etc | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Sweep Bend R1.5D, R3D | DN110-1200mm | PN16, PN12.5, PN10, PN8 |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

| HDPE Fabricated Fittings | ||||

|

|

|||

|

|

|||

|

|

|||

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Applications of High Density Polyethylene (HDPE) fabricated segments fitting

The HDPE fabricated fittings made from polyethylene pipes is a cost effective solution for a broad range of piping challenges in mining, industrial, mechanical, marine and agricultural applications. It has been tested and proven effective for above ground, surface, buried, sliplined, floating, and sub-surface marine applications.

Options available to you include; spools, manifolds, offsets, launders, overflows and purpose made tanks. With expert knowledge and efficiency, we’ll ensure that everything is pre-fabricated to your specifications.

The fabricated fittings made by high-density polyethylene (HDPE) pipe are often used for many applications:

- potable water

- wastewater

- slurries

- chemicals

- hazardous wastes

- Marine

- Dredging

- Mining Site

|

|

| Fabricated HDPE Tee for Drainage | Fabricated HDPE Fittings for Mining Application |

|

|

| Butt Fusion and Ef Fittings for Water Pipeline | Customized HDPE Tee for Mining |

High Density Polyethylene (HDPE) fabricated segments fitting

High Density Polyethylene (HDPE) fabricated segments fitting |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

||||

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español