Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

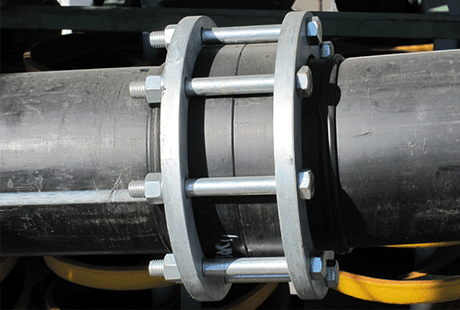

High Pressure HDPE fitting SDR9& SDR7

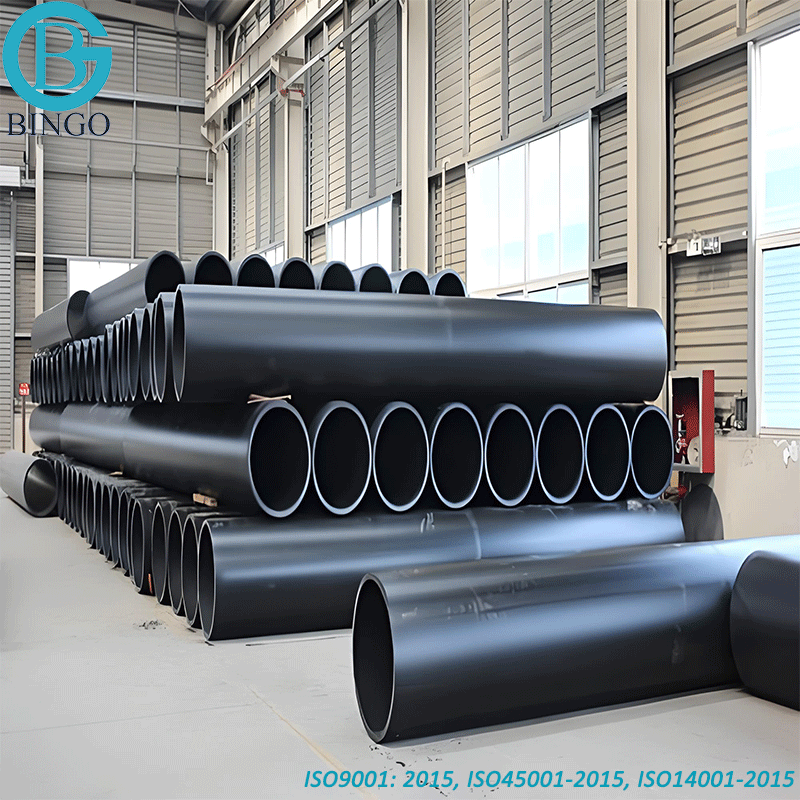

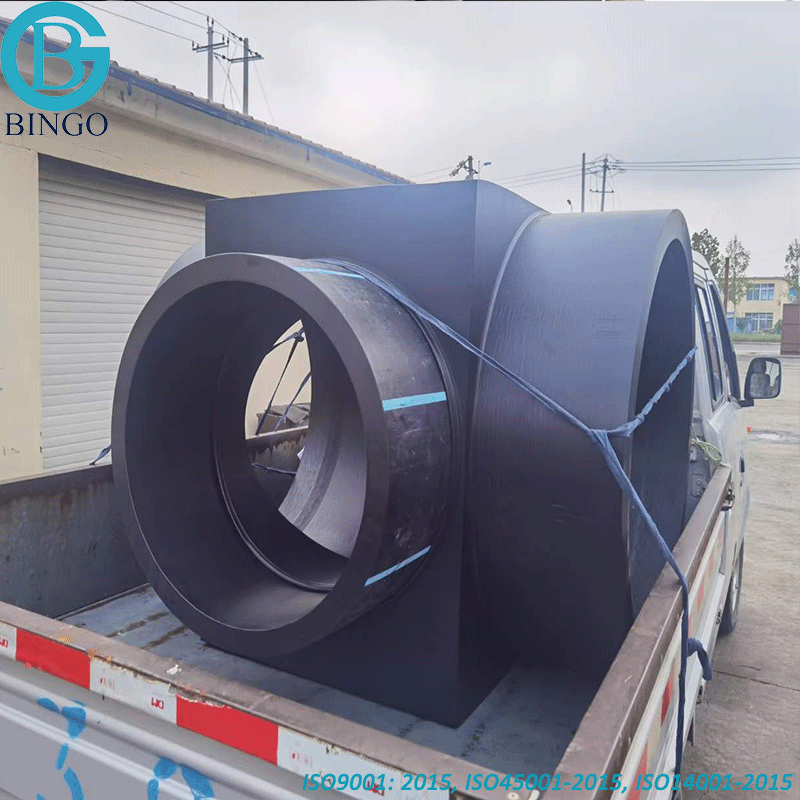

Our high pressure rate butt fusion fittings include the stub ends, tee, eccentric reducer, and the concentric reducer, end cap and other customized fittings from the diameter from 50mm to 2000mm, available for the pressure rate from PN10 to PN32(SDR17 to SDR6).

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: Packaged by cartons or bags

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Pressure High Density Polyethylene (HDPE) fitting

| Products details information | |

| Product name | High Pressure High Density Polyethylene (HDPE) fitting |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN110-1400mm(4 inch- 56 inch) |

| Pressure Class | From PN10 to PN32/SDR17-SDR6 |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | HDPE Fittings for water, oil and gas, mining, marine, drainage, chemincal, Irrigation, fire fighting... |

| Color | Black |

| Category | HDPE Fabricated fittings, sweep bend, tee, elbow, reducer tee, cross... |

| Matching products | HDPE pipe fittings, Customized PE fittings, DI/ Steel backing ring flanges, Valves, water meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High pressure High Density Polyethylene (HDPE) fitting

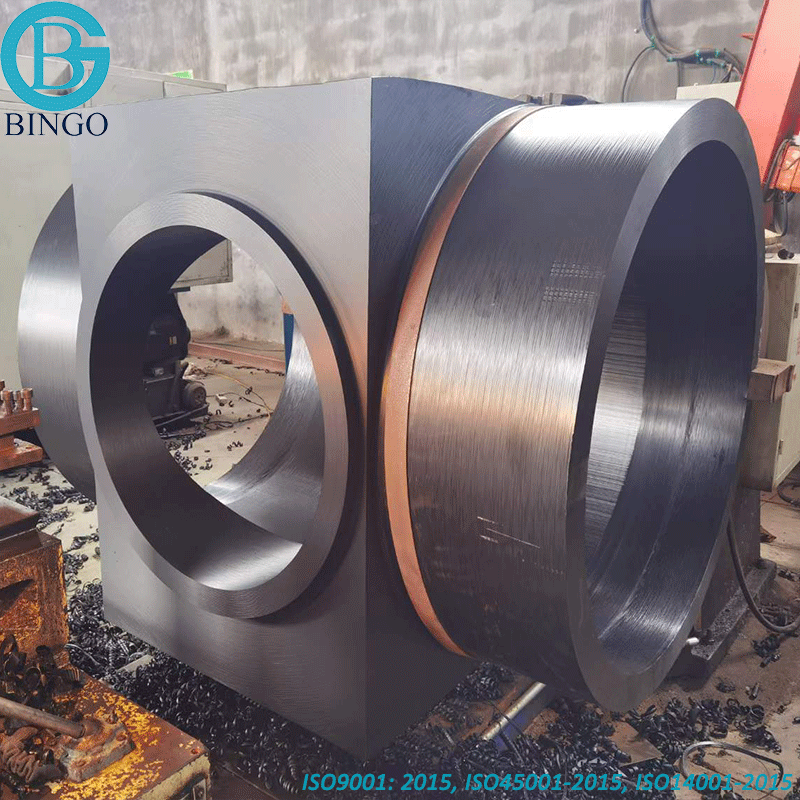

High pressure butt fusion fittings processed from the HDPE hollow bar by the CNC machine. Our high pressure rate butt fusion fittings include the stub ends, tee, eccentric reducer, and the concentric reducer, end cap and other customized fittings from the diameter from 50mm to 2000mm, available for the pressure rate from PN10 to PN32(SDR17 to SDR6).

All these specialized proceed butt fusion fittings are produced by HDPE hollow bars, which could withstand stronger pressure class then the injection molded fittings, no pressure reduction. All these fittings and hollow bar are made from the virgin PE100 compounds, which could be used for water supply, gas, oil and petroleum, dredging, marine, mining, chemical, fire fighting, water treatments and industrial, especially for some harsh using conditions.

This kind of HDPE butt fusion fittings solve the problems for high pressure rate fittings, like PN20, PN25, PN32 applications, it could process some different shaped fittings, which couldn’t be injected molded, like the HDPE puddle flanges. At the same time, it will not limited by the mould, and could be ordered by small quantity or trial order, which save much cost for clients.

The outside diameter of the hollow bar could reach to 2300mm, and the maximum outside diameter of PE solid rods 1400mm, which could be processed to different pressure rate and different shaped fittings according to clients’ requirements, which could not be produced by ordinary forming technology. All these fittings are widely used for many application, produced in accordance with ASTM, ISO 4427, EN12201, EN1555 standards etc., and had been exported to many countries.

Advantages of High pressure High Density Polyethylene (HDPE) fitting

High-density polyethylene (HDPE) fittings can meet and withstand these challenges and has several proven advantages for many applications.

Stronger enough with the pipes.

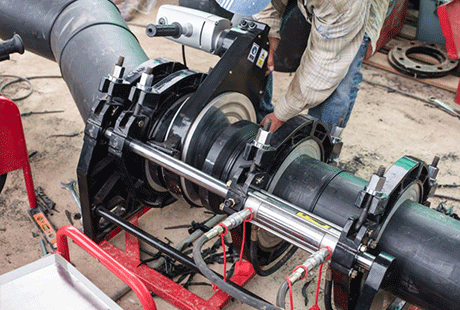

Butt fusion with the pipes and other fittings, easy installation.

Abrasion resistance. Abrasion resistance in polyethylene piping and fittings systems is far superior to metallic piping systems due to its wear and scouring resistance.

Chemical resistance.HDPE pipe offers superior chemical-resistance due to the inherent inert properties of polyethylene polymer it is comprised of.

Lower cost. Because HDPE pipe and fittings are low-maintenance and features leak-free joints, it’s extremely cost-effective.

A conservative estimate for the lifespan of HDPE pipeline is between 50 and 100 years.

Specification of High Pressure High Density Polyethylene (HDPE) fitting

| Item | Fittings Types | Specified Fittings | Diameter(mm) | Pressure Rates(PN-Bar) | Manufacturing Process |

| 8 | Customozed High Pressure PE fittings | Stub End | OD20-2000mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | CNC Lathe Process |

| Tee | OD200-900mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Mud Tee | OD200-900mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Concentric Reducer | OD110-1200mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Eccentric Reducer | OD110-1200mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| End Cap | OD80-1600mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Hollow Bar | OD80-1600mm | - | Extruded | ||

| Solid Bar | OD80-1600mm | - |

High Pressure HDPE Butt Fusion fittings DN50-2000mm SDR7.4& SDR9

| High Pressure HDPE fitting SDR9& SDR7 | ||||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Applications of High Pressure High Density Polyethylene (HDPE) fitting

- High Pressure water projects

- Chemical installations

- Civil engineering

- Marine land reclamation

- Landfill engineering

- Renewable energy

- Petroleum area applications

- Mining projects

- Potable water networks

- Drinking water projects

|

|

| Fabricated HDPE Fittings for Mining Application | Butt Fusion Fittings for Chemical |

|

|

| Butt Fusion HDPE Stub End for Water Pipe Connecting | Butt Fusion HDPE Pipe for Mining & Industrial Piping Solutions |

High pressure High Density Polyethylene (HDPE) fitting

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español