Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

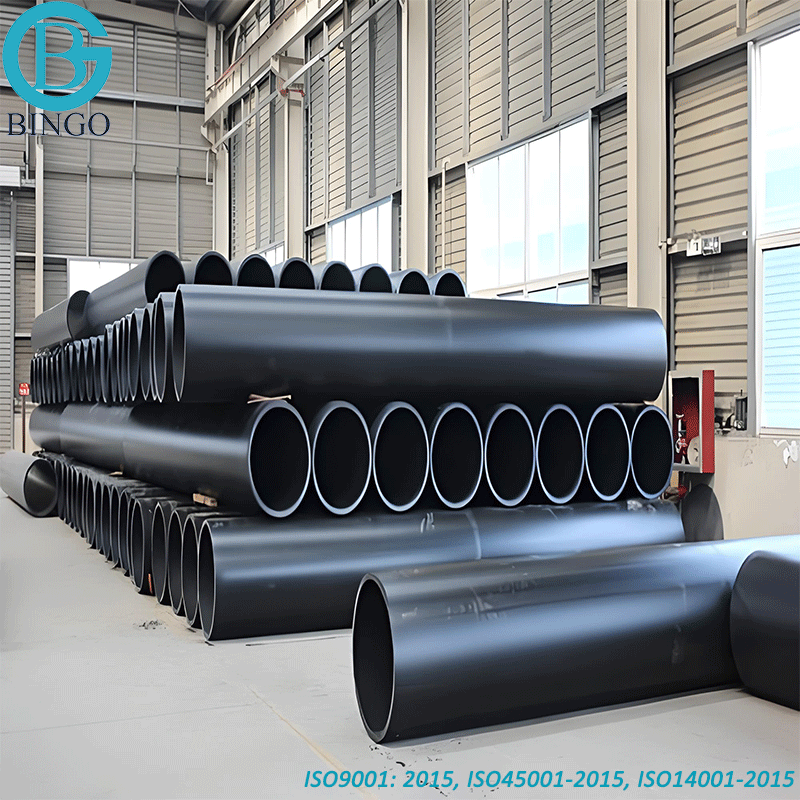

HDPE Pipes and Fittings for Fire Fighting

Many industrial companies operate special fire fighting system to prevent property losses. A complete fire fighting system needs the underground pipelines as the main lines, with easy accessible fire hydrant connections. The material PE100 or PE100RC is slowly advancing to one of the most used materials for fire-fighting applications.

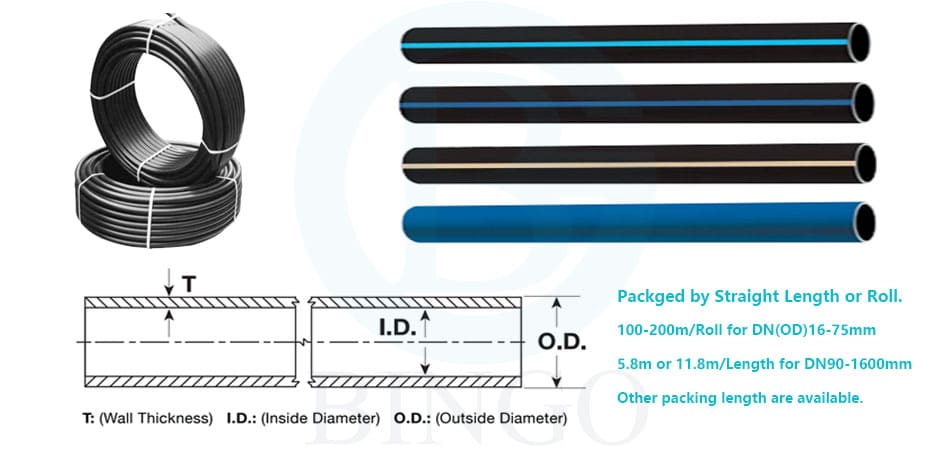

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: 11.8m or 5.8m/ Pcs for straight

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of HDPE Pipes and Fittings for Fire Fighting

| HDPE fire fighting pipe and fittings details information | |

| Product name | High-density Polyethylene Pipes and Fittings for fire fighting applications |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Pressure Class | From PN4 to PN32 |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | Water Supply, Drainage, Industry, Fire Fighting, Chimical... |

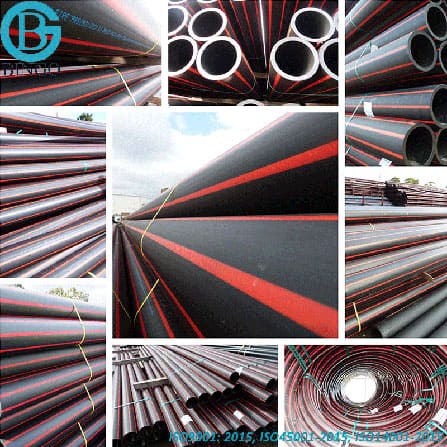

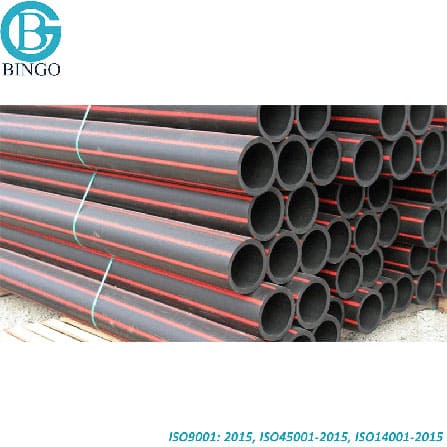

| Color | Black with blue stripes, black or others colors |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714... |

| Matching products | HDPE pipe fittings, PE flange, Fire Pump, Customized Fittings, Fabricated fittings, Stainless Steel Flanges, Blind Flanges,Fire Hydrant, Welding Machines and Tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of HDPE Pipes and Fittings for Fire Fighting

High-density polyethylene(HDPE) pipes provide many benefits for many fire-fighting applications. Compared with materials such as ductile iron pipes and steel pipes, they are non-corrosive, have excellent chemical resistance and excellent wear resistance. HDPE pipes have been widely used in mining and chemical industry, fire protection industry. In addition to the performance and life cycle cost advantages, PE pipes are light in weight, long in pipe length and flexible, so they are easy to install and safe.

Requirements of HDPE Pipes and Fittings for Fire Fighting

Materials. High quality and virgin PE 100 and PE 100-RC materials that are listed by the PE 100+ association.

Pipes. Pipes should be produced according to ISO 4427, EN 12201, ASTM 3350,and/or AWWA C906.

Fittings. Fittings should be produced according to ISO 4427 and EN 12201, and certified according to EN 12201 standard. Whenever available, injection molded fittings should be used preferably.

Approved Manufacturer. Manufacturer must be ISO-9001 and ISO 14001 certified. An inspection certificate according to EN 10204 (3.1) must be provided by the manufacturer on request. Pipes and fittings should be produced and supplied by the same company as a complete system.

Pressure rating. HDPE pipes and fittings shall have a pressure rating at operating temperature of 20 °C based on minimum 50 year design life and including a safety factor of 1.25. The pressure class of high-density polyethylene(HDPE) pipes and fittings for the fore fighting should be from PN16 to PN32(SDR11 to SDR6).

Connection of HDPE pipes and fittings

Bingo HDPE pipes and fittings for firefighting systems are generally joined by heated tool butt welding, electrofusion welding or mechanically through the use of flanges. The appropriate connection technique depends on the location and the project requirements itself. Detailed guidelines for all connection techniques are available on request.

1.Heated tool butt welding

At the heated tool butt welding process, the joining zones of the components to be welded are aligned under pressure on the heated tool (alignment), heated up to the welding temperature with reduced pressure (heating up) and joined under pressure (joining) after removal of the heated tool (changeover).

2.Electrofusion welding

Bingo Electro-fusion fittings can be used to weld the required components using resistance wire (heating wire). The heating wire is completely embedded in the fitting. This provides a smooth inner surface and allows an easy cleaning and insertion of the pipe ends/spigots. Universal welding machines are suitable and provide the required power supply.

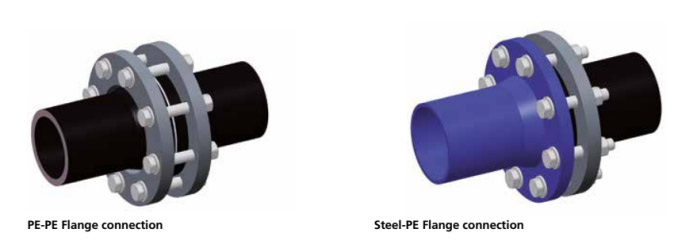

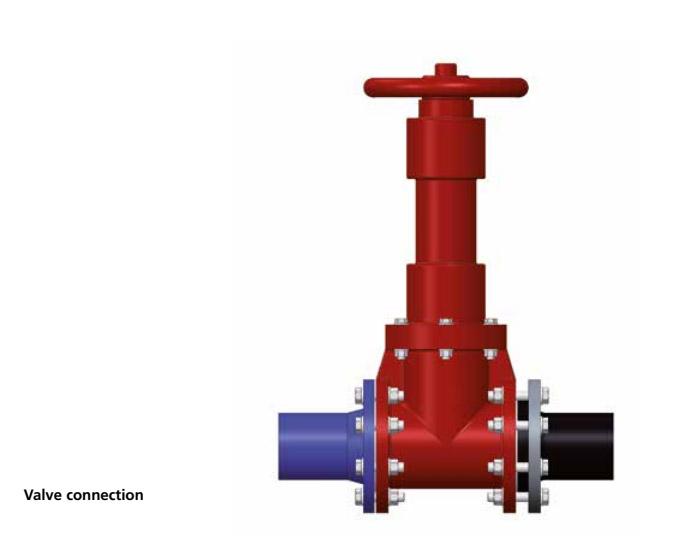

3.Flange connections:

Flange connections are used to create detachable connections between PE and PE, or as transition from PE to other materials (e.g steel, ductile iron, fire hydrant. For example when pipes are connected to valves).

The advantages of the HDPE Pipes and Fittings for Fire Fighting

The complete HDPE fire-fighting piping system, fittings and joints can be heated and welded together with with the pipe. High strength and rigidity, can withstand internal pressure and external load.

Chemical resistance to withstand corrosive chemicals (pH from 1 to 14) and aggressive soils.

Good toughness, light weight, good impact resistance, can reduce installation costs, and narrow trenches can reduce excavation work.

The flexibility of cold bending can follow the contour of "ground laying" and reduce the need for directional fittings.

The hydraulically smooth, non-wetting pipe hole maintains low flow resistance throughout the life of the system.

Will not rust, rot, corrode or nodule.

Non-conductive, does not require cathodic protection from stray ground currents for minimal long-term maintenance.

Long-term, low-resistance fluid flow reduces pumping and operating costs.

It is resistant to environmental stress cracking and can play a long-term role in harsh environments.

Fully restrained system, no external tie rods or restraints. Butt welding, flange connection and mechanical joint tightening joints are fully constrained, thereby eliminating the need for thrust blocks and external joint constraints.

Polyethylene pipe has excellent resilience, flexibility and short-term mechanical strength that provide exceptional surge tolerance and resist water hammer. A low elastic modulus provides adampening mechanism for shock loads. These properties result in lower surge pressures compared to more rigid systems such as steel, ductile iron or PVC pipes and fittings.

Specifications of HDPE Pipes and Fittings for Fire Fighting

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | PE100 | ||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | |||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | |||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

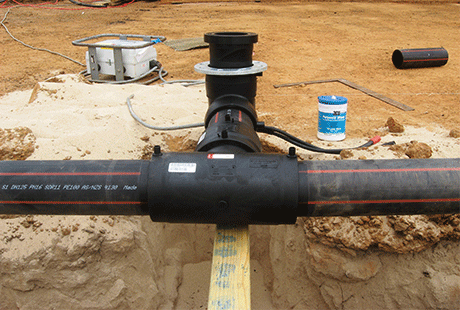

Application of HDPE Pipes and Fittings for Fire Fighting

- Polyethylene pipe has unique properties, making it the preferred material of for fire protection of company assets. Widely used in industrial and municipal fire protection systems, and in factories, chemical plants and manufacturing plants. PE pipes, PE fittings and valves are also essential products in the fire protection systems of power plants, refineries, petrochemical companies, airports and international industrial projects.

- Shopping mall fire protection system

- Underground fire protection system in metro station

- Airport fire protection system

- Pharmaceutical factory

- Chemical plant

- Refueling stations

|

|

| HDPE Pipes for Underground Firewater Systems | HDPE Pipes for Underground Fire Protection Systems |

|

|

| HDPE Pipes for Municipal Fire Protection | HDPE Pipes for Power Stations |

HDPE Pipes and Fittings for Fire Fighting

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español