Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

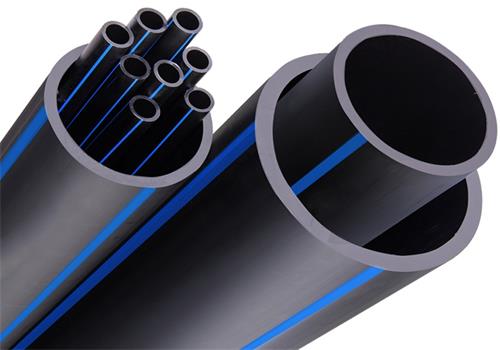

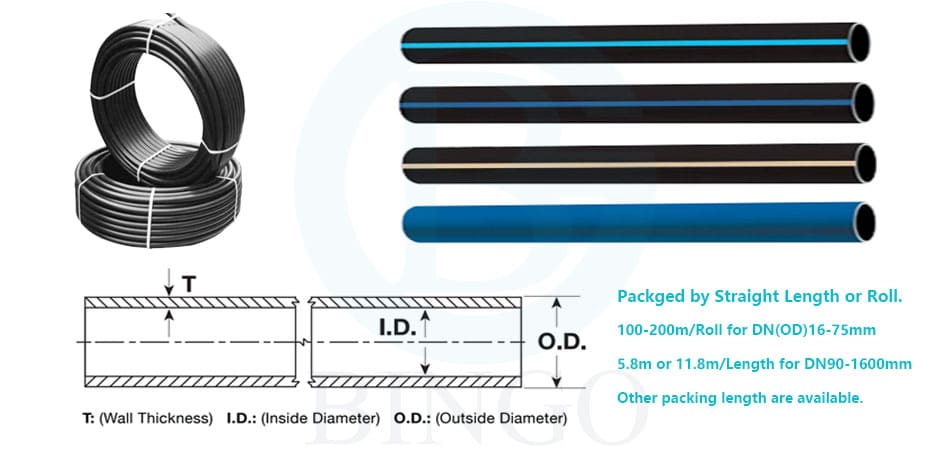

Coiled HDPE Pipes OD20-110mm

Our product range includes a wide range of HDPE coil pipe, HDPE roll pipes, HDPE irrigation roll pipes and HDPE pipe coil for the small diameter pipes less than OD 110mm.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene Coiled Pipes and Fittings

| Products details information | |||||

| Product name | High Density Polyethylene Coiled Pipes and Fittings | ||||

| Brand | Bingo pipeline(Customer brand is available) | ||||

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) | ||||

| Pressure Class | From PN4 to PN32 | ||||

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... | ||||

| Application | Waste discharge, Drainage, Mining, Slurry, Sewer, Water Reticulation, Stormwater Systems ... | ||||

| Color | Black with blue stripes, black or others colors | ||||

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714... | ||||

| Matching products |

|

||||

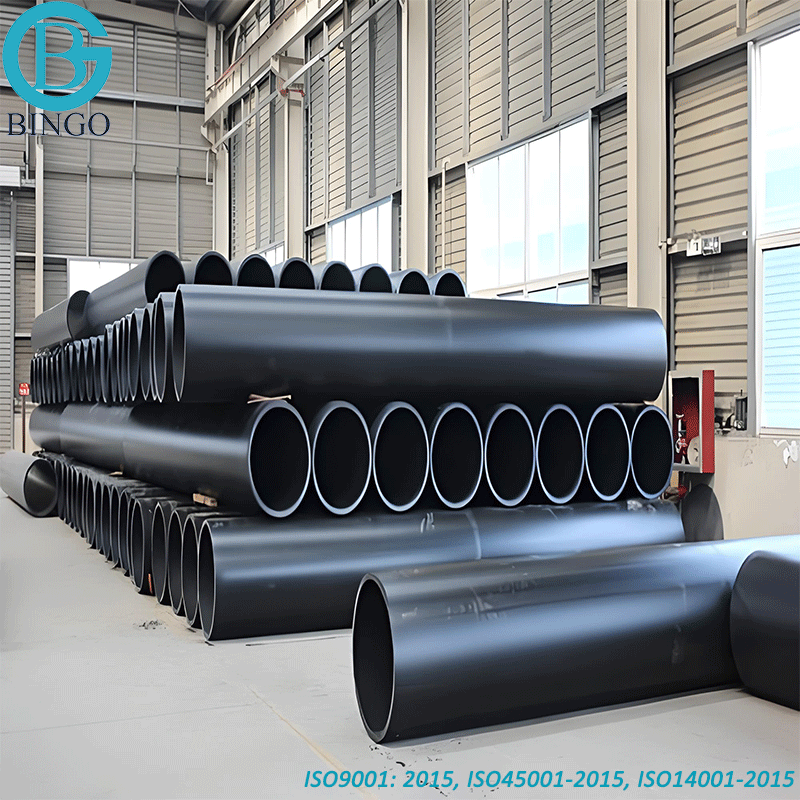

| Company/Factory Strength | |||||

| Production Capacity | 120*40ft containers/month | ||||

| Sample | Free sample could be provided | ||||

| Quality | QA & QC system, Ensure traceability of each process | ||||

| Warranty | 50 years with normal use | ||||

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... | ||||

| Delivery time | 5-30 days, depending on the quantity | ||||

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection | ||||

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service | ||||

| Management | Effective 8S Management System | ||||

| No. of employees | More than 300 people | ||||

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of HDPE Coiled Pipes

These coiled HDPE pipes are often used in Sewerage and Drainage systems, Industrial effluent disposal systems, Cable Ducting , Portable water supply, Irrigation/ Agriculture, Sprinkler System, Gas Distribution. Which could be connected by the compression fittings and socket fusion welding fittings, butt fusion welding and electro fusion fittings, flanges connection.

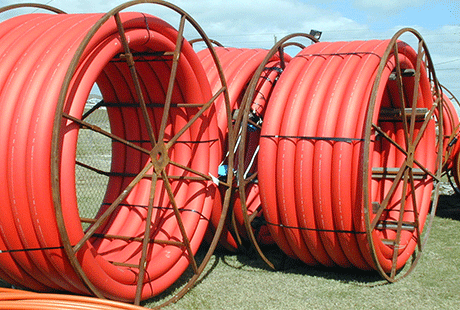

The flexibility of high-density polyethylene (HDPE) conduit allows most diameters to be coiled for winding onto reels or into coils for transportation in long continuous lengths. This greatly improves the speed and efficiency of field installations.

The coiling of HDPE conduit produces stress throughout the pipe wall, resulting in ovality; the extent of ovality is initially dependent on the radius of curvature and outside diameter of the conduit. Coiling will also result in varying degrees of coil-set over time.

The magnitude of both ovality and coil-set are dependent on wall thickness of the conduit, radius of curvature, time under stress, temperature-cycling, and the conduit diameter vs. radius of curvature.

With state-of-the-art infrastructure facilities, we are able to provide a large array of HDPE Pipe Coils in industry. By utilizing the world-class raw material and sophisticated technology machines, these coils are designed and developed under the vigilance of our heads, who keep an eye on every stage of the production processes to ensure that they are free from any defect and reliable in nature.

Trenchless Installations: Methods of installing conduit that does not require digging a trench for installation of the conduit. Trenchless methods include:

1.Horizontal Directional Drilling (commonly referred to as HDD)

A technique for installing pipes, such as conduit, below ground using a surface-mounted drill rig that launches and places a drill string at a shallow angle to the surface and has tracking and steering capabilities.

2.Stitch Boring

A technique whereby a series of pits are hand dug, and a pneumatically-driven earth piercing tool is used to bore a hole from pit to pit, creating a hole into which the conduit can be pulled.

3.Plowing

A technique whereby a plow is inserted and dragged through the ground, creating a furrow into which the conduit will be installed. Two sub-types of plowing exist:

3.1. Chute Plowing: conduit is fed through a chute trailing the plow into the bottom of the furrow created in the ground

3.2. Pull Plowing: conduit is pulled into the furrow from a pit as the plow is being pulled through the ground.

Re-rounding: The action of physically correcting ovality by the use of either clamping tools or equipment that applies mechanical pressure to re-round the conduit. Since the pipes are coiled long length, maybe the pipes will be flexed, and it cold be re-rounded by the tools and do not affect usage effect.

| Packing of HDPE Coilded Pipe | ||

|

|

|

| 200m/ Roll for OD20-40mm | 100m/ Roll for OD50-75mm | 5.8 or 11.8m/Length for more than 90mm |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

A third packaging option less frequently used is straight lengths, sometimes called “sticks”, often used for nominal diameters of 3 inch and larger.

HDPE conduit straight lengths are typically available in lengths up to 40 feet(12 m). Sticks are often used for diameters larger than nominal 3 inch, simply because those diameters are too large to coil and be transportable in conventional trucks and container. These sizes not be supplied on reels or coils due to the potential for excessive ovality and buckling. Which should only be supplied in straight lengths or“sticks”. Contact conduit manufacturers for additional information.

HDPE conduit is initially manufactured with minimal ovality, typically less than 3%. Due to its flexible nature, HDPE conduit can become oval or out-of-round when it is wound onto reels or coils. Ovality is a packaging condition that occurs when conduit is coiled, whereby conduit flattens out as it is coiled. This is allowed and specified in industry standards.

Factors Influencing Ovality

The amount of ovality in conduit that results from coiling can vary, based on several factors. The primary factor is the diameter of the conduit, while the secondary factor is the bend radius of the coiled conduit.

Other factors which influence the percentage and permanence of the ovality are:

Pipe stiffness

Wall thickness

Creep resistance

Time stored in the coiled configuration

Ambient temperature and temperature cycles while in storage

Depending on the methods used for tying or wrapping conduit in reels or coils, the beginning and end of each coil, possibly several feet in length, should be cut off and discarded as it is likely to have been deformed when the ends of the coil were secured.

Advantages of High Density Polyethylene (HDPE) Coiled Pipes and Fittings

High Tensile Strength & High Stress Crack Resistance prevents inching growth of cracks.

High resistance to UV & direct sunlight

Leak proof joints.

Light weight and flexible.

Few joints are needed, easy to install and transport, reduce cost.

Excellent flow characteristics due to smooth inner surface hence low frictional loss

Weather Resistant

Excellent corrosion, abrasion and chemical resistance. Inert to most acidic and alkaline solutions

HDPE pipes have good ductility and toughness

Available in coils and straight length of 5m, 6m, 12m.

Specifications of High Density Polyethylene Coiled Pipes and Fittings

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 1.0 | 17.98 | 0.6 | 18.72 | 0.61 | 18.72 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 1.2 | 22.48 | 0.8 | 23.39 | 0.76 | 23.39 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 1.5 | 28.77 | 1.0 | 29.94 | 0.97 | 29.94 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 2.0 | 35.76 | 1.2 | 37.43 | 1.21 | 37.43 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 2.4 | 44.91 | 2.0 | 45.76 | 1.52 | 46.79 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Application of High Density Polyethylene Coiled Pipes and Fittings

- HDPE Agricultural Pipes

- HDPE Sprinkler Pipes

- Cable Ducting

- Drinking Water

High Density Polyethylene Coiled Pipes and Fittings

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español