Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

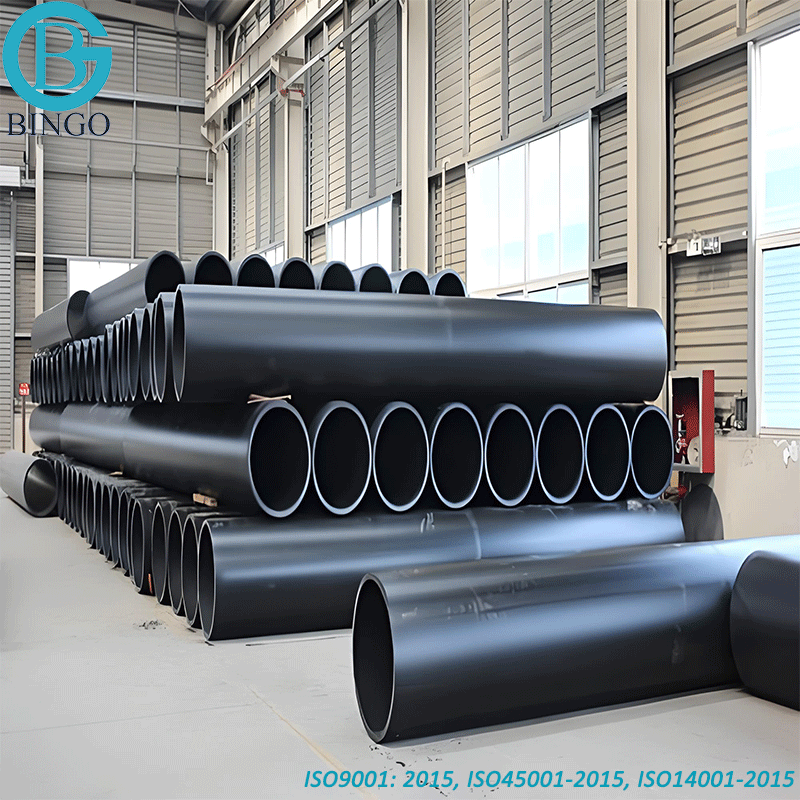

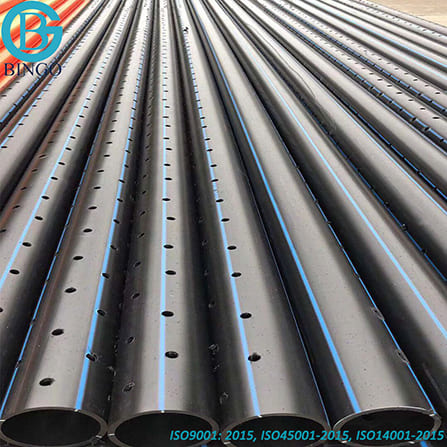

HDPE Perforated Drain Pipe and Fittings

HDPE Perforated drainage pipes are used in waste water collection areas, mines, muddy land water reclamation, drainage systems of highways and drainage systems requiring drainage where the weight of future external loads on the pipe is dense.

- 1.Delivery: 10-30 days depending on the total quantity.

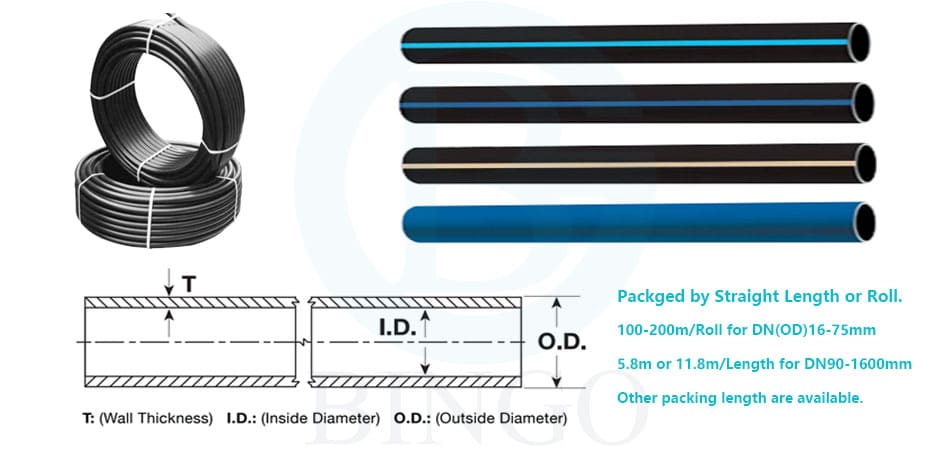

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings

| Products details information | |

| Product name | High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | Waste discharge, Drainage, Mining, Chemical, Sewer, Leachate, Landfill... |

| Color | Black with blue stripes, black or others colors |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714... |

| Matching products | HDPE pipe fittings, PE flange, Water Pump, Customized Fittings, Fabricated fittings, Stainless Steel Flanges, Blind Flanges, Welding Machines and Tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings

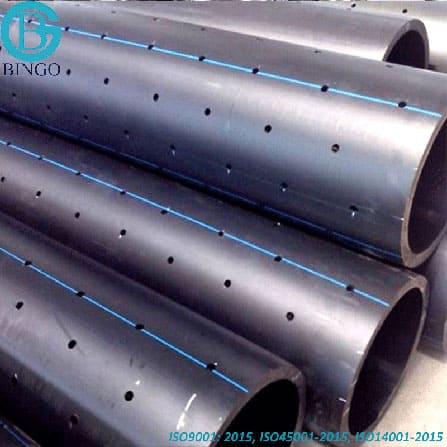

PE Perforated pipes is a new type of pipe having a water-filtered (discharge) function, which overcomes many of other disadvantages of other drainage pipes, because of its unique design and good performance of materials, It has strong drainage and water seepage effect. Using the "capillary" phenomenon and "siphon" principle, set water absorption, water permeability, drainage as one of the solution, with engineering design requirements of pressure resistance, water permeability and filtration. It will not fracture due to geological and geographical temperature changes, and can achieve the effect of discharging clean water, will not cause secondary pollution to the environment, belongs to a new type of environmental protection products. Its construction is simple, no need joints, no special requirements for geology, terrain, it could be used for any areas where the underground drainage is required.

HDPE Perforated pipes have good chemical durablity that carry wastes, chemical mine waste, motor oil and mixed road waters. Due to its much light weight tan the concrete and iron or steel pipes, no need more mechanical work when construction, this is the reason why HDPE perforated pipes has cost advantages, it is easy to install, transport and store. The inner and outer surface are smooth, the Friction is small without a blockage. The ring stiffness is large, could bear high external loads, which can prevent the pipeline from collapsing. In addition, HDPE pipes are flexible, could adapt to the ground movement without breaking, deforming or cracking. The minimum service life will be more than 50 years.

Nowadays, the perforated drainage pipe system is widely used in the construction of sponge city. The design of sponge city should coordinate the system of natural precipitation, surface water and groundwater, coordinate the water supply, drainage and other water recycling links, and consider its complexity and long-term effect. The collection of surface and shallow rainwater through infiltration technology is the primary step in the entire water recycling development. However, traditional seepage pipes or perforated pipes either fail to achieve the expected leakage effect or are too expensive, making the construction of sponge city to be perplexed. Binggao pipeline as a research and development, production, sales as one of the scientific and technological innovation enterprises, we have successfully developed a new type of PE perforated drainage pipe that is very suitable for sponge city construction through a large number of scientific theoretical demonstrations and engineering practices, good result have been obtained.

The advantages of High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings

The pore size is small, and the opening rate of the pipe surface is more than 85%, which has good drainage; it is permeable in all directions and has good permeability;

High compressive and tensile strength, long service life;

Good corrosion resistance and anti-microbial erosion;

Light weight, few joints and convenient connection;

Using PE as raw material, it is flexible, good bonding with soil, non-toxic and safe;

Antioxidant and carbon black are added during the processing process, which has better anti-ultraviolet performance and aging resistance;

The ring stiffness is relatively high. Tested by professional institutions, the ring stiffness can reach more Easy to connect. Usually black PE pipe or gray PVC pipe;

With laser marking on the pipes, traceable for long term.

Specifications of High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 1.0 | 17.98 | 0.6 | 18.72 | 0.61 | 18.72 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 1.2 | 22.48 | 0.8 | 23.39 | 0.76 | 23.39 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 1.5 | 28.77 | 1.0 | 29.94 | 0.97 | 29.94 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 2.0 | 35.76 | 1.2 | 37.43 | 1.21 | 37.43 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 2.4 | 44.91 | 2.0 | 45.76 | 1.52 | 46.79 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Applications of High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings

- 1. Sponge city construction

- 2. Perforated pipe for slope protection of river embankment

- 3. Collection of groundwater leachate in landfill site, waste discharge, etc.

- 4. Other shallow water collection and drainage works

- 5. Widely used in landfills, landslide reconstruction,

- 6. The seepage liquid collection pipe, seepage pipe, and biogas collection pipe in the landfill

- 7. Sub surface drainage system for roads/highways

- 8. Golf courses

- 9. Sub surface drainage system for draining excess water from lawns/gardens/agricultural farms

- 10. Airport runway sub surface drainage system

|

|

| HDPE Pipes for Waste Water Mains | HDPE Pipes for Drainage |

|

|

| HDPE Pipes for Dredging Project | HDPE Pipes for Power Plant Operations |

High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español