Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

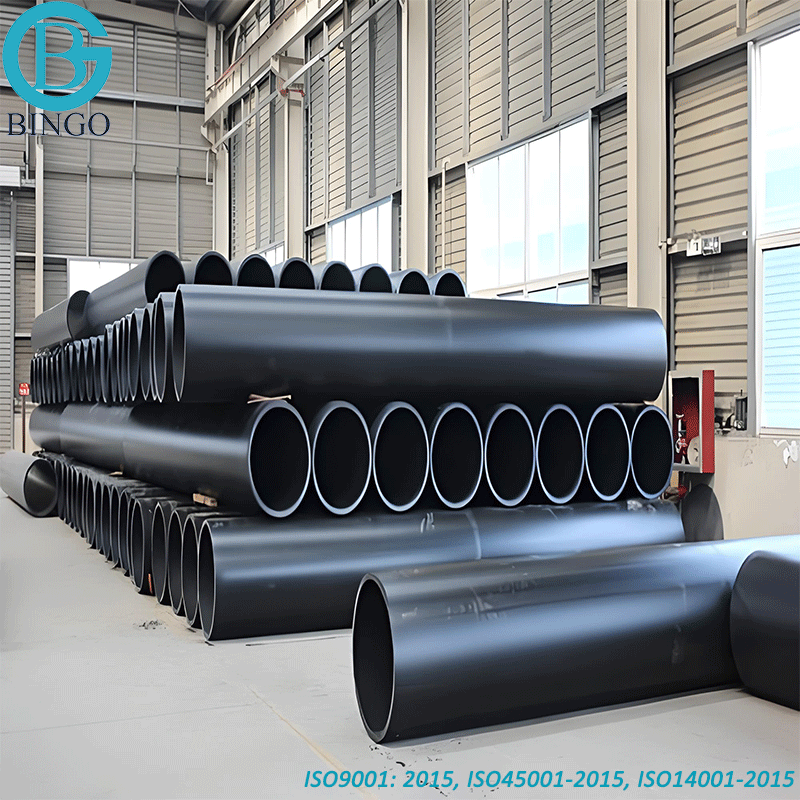

HDPE Trenchless Pipes For HDD

HDPE pipes are ideal for pulling through long, underground holes as they are flexible, robust, and resistant to almost all aggressive elements. These plastic pipes offer a new generation of leak-proof, maintenance-free, and energy-efficient pipeline systems that are chemical- and abrasion-resistant and therefore excellent for use in the lining and relining of pipelines, slurry applications, water reticulation, sewer and stormwater systems, the mining industry, and in dolomite areas.

- 1.Delivery: 10-30 days depending on the total quantity.

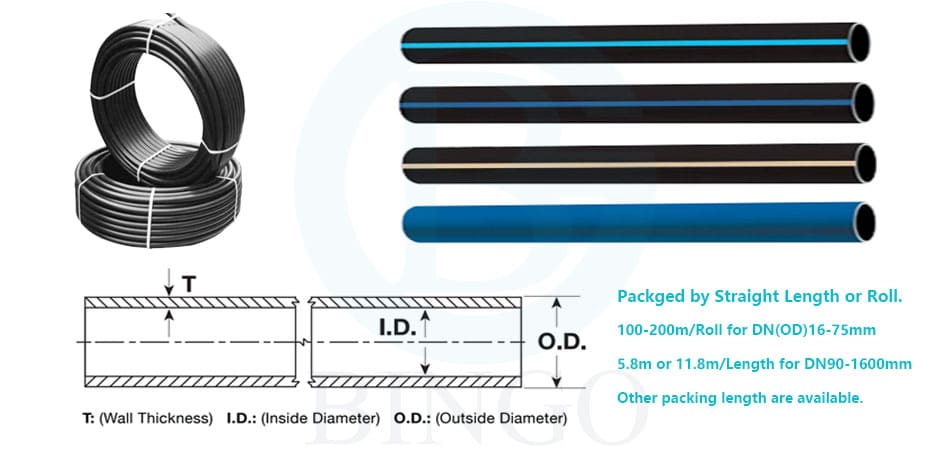

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene Trenchless Pipes For Horizontal Directional Drilling

| Products details information | Company/Factory Strength | ||

| Product name | High Density Polyethylene Trenchless Pipes For Horizontal Directional Drilling | Production Capacity | 120*40ft containers/month |

| Brand | Bingo pipeline(Customer brand is available) | Sample | Free sample could be provided |

| Dia Ranges | DN63-800mm(2 inch-32 inch) | Quality | QA & QC system, Ensure traceability of each process |

| Application | Waste discharge, Drainage, Mining, Slurry, Sewer, Water Reticulation, Stormwater Systems ... | Warranty | 50 years with normal use |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... | Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714... | Delivery time | 5-30 days, depending on the quantity |

| Length | 5.8m or 11.8m/ length with the flanges ends(customizable) | Test/Inspection | National Standard Laboratory/ pre-delivery inspection |

| Place of Origin | China | Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Pressure Class | From PN4 to PN32 | Management | Effective 8S Management System |

| Color | Black with blue stripes, black or others colors | No. of employees | More than 300 people |

| Matching products: HDPE pipe fittings, PE flange, Water Pump, Customized Fittings, Fabricated fittings, Stainless Steel Flanges, Blind Flanges, Welding Machines and Tools, etc. | |||

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene Trenchless Pipes For Horizontal Directional Drilling

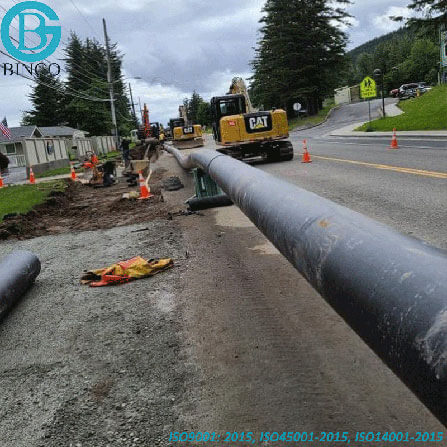

HDPE pipe are widely used for trenchless sewer lateral replacement. HDPE is the safest and most efficient option for sewer pipe replacement. “High-density polyethylene” pipes are now widely used in the sewer industry.

The development of trenchless technology to rehabilitate existing underground infrastructure with minimal disruption to surface traffic, business, and other activities, has left a lasting impact on the construction and civil engineering industries.

As the name denotes, trenchless technology requires few or no trenches to be dug for the maintenance work to be done and can be defined as, “A family of methods, materials, and equipment capable of being used for the installation of new or replacement or the rehabilitation of existing underground infrastructure.”

Because trenchless technology greatly reduces the need for invasive excavations, it has a much smaller impact on the surrounding environment, both ecologically and socially. Residential neighbourhoods remain unscathed, commercial districts do not have to deal with loss of business, and rural regions remain undisturbed. Noise and air pollution are also kept to a minimum and rehabilitation time is short.

As the use of trenchless technology continues to grow in popularity and use, so too does the importance of using top-quality pipe material that meets the specific requirements of the particular technique being used. The plastics pipe industry is a strategic industry, where hardware needs to be reliable for extended periods of time. According to industry standards, quality plastic pipe should endure in excess of 100 years without failure. Especially HDPE raw materials have good adhesion and toughness. They also have many advantages in terms of cost-effectiveness, minimal impact on the environment, and safer processes. The use of HDPE pipes in trenchless technology is rapidly becoming a repair building and civil engineering The preferred method of domain pipeline. These pipelines can not only provide a design life of 100 years, but also provide solutions to major industry challenges such as corrosion and high leakage rates.

Advantages of the High Density Polyethylene Trenchless Pipes For Horizontal Directional Drilling

The biggest advantage of HDPE HDPE trenchless pipes for HDD besides its long-life expectancy, is its heat-fused joints, which make the pipe a single homogenous pipeline. Joints in traditional piping materials are the biggest source of leakage. Those joints are also the pathway for contaminates to enter the pipe system.

The project quality is good. The traversing pipeline can fully meet the design curve and deep buried, and the quality is safe and reliable.

It is conducive to protecting the environment and does not affect the normal passage of roads.

The number of construction personnel is relatively small, and at least 10-20 people are required for manual excavation, while only 7 people are used for pipeline directional drilling technology.

The construction area is relatively small and the construction period is relatively short.

Engineering materials are greatly saved.

It has a wide range of applications and is not affected by water currents, climate and environment. It can be used on land, sea, urban areas and rivers.

Compared with traditional trenching and buried pipes, it has better technical, environmental protection and economical efficiency, and is suitable for crossing streets, highways, railways, buildings, and rivers, especially in downtown areas, historic sites, green belts, where excavation is impossible or unsuitable areas.

Specifications of High Density Polyethylene Trenchless Pipes For Horizontal Directional Drilling

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 1.0 | 17.98 | 0.6 | 18.72 | 0.61 | 18.72 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 1.2 | 22.48 | 0.8 | 23.39 | 0.76 | 23.39 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 1.5 | 28.77 | 1.0 | 29.94 | 0.97 | 29.94 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 2.0 | 35.76 | 1.2 | 37.43 | 1.21 | 37.43 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 2.4 | 44.91 | 2.0 | 45.76 | 1.52 | 46.79 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Application of High Density Polyethylene Trenchless Pipes For Horizontal Directional Drilling

- Used in the oil industry to cross the river oil pipeline

- Used in power system for the telecommunications cable conduit

- Used in the construction of municipal drainage pipelines

- Municipal sewage treatment system

- Water and gas pipeline network transformation

HDPE trenchless pipes for HDD(horizontal directional drilling)

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español