Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

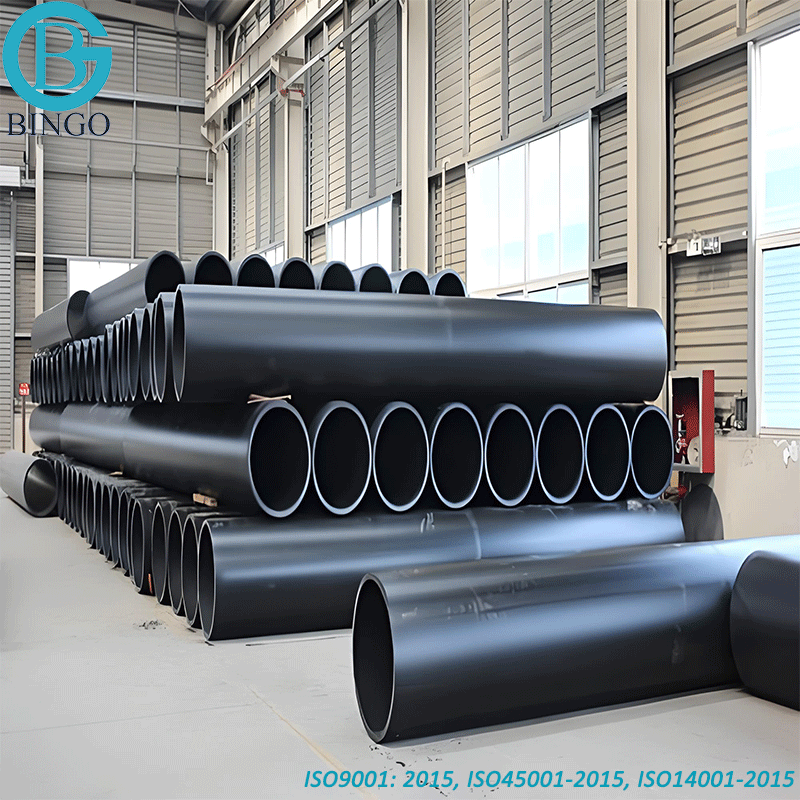

HDPE Pipes for Cable Protection

We produce a wide variety of protection pipes in PE and PVC for telecommunication and power cables, as well as fiber optic cable protection, which can also be used for underground and underwater, onshore applications.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: Packing: 11.8m/ Pcs for 40ft or 5.8m/ Pcs, 1000-3000m by coils for DN20-63mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings

| Products details information | |

| Product name | High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-500mm(1/2 inch-20 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | drinking water, fresh water, drainage, mining, dredging, marine, industry, chemical... |

| Color | Black with blue stripes, black or others colors |

| Standards | ISO4427, EN12201, ASTMD3035, ASTM F714... |

| Matching products | HDPE pipe fittings, Customized PE fittings, Quick Joints, DI/ Steel backing ring flanges, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

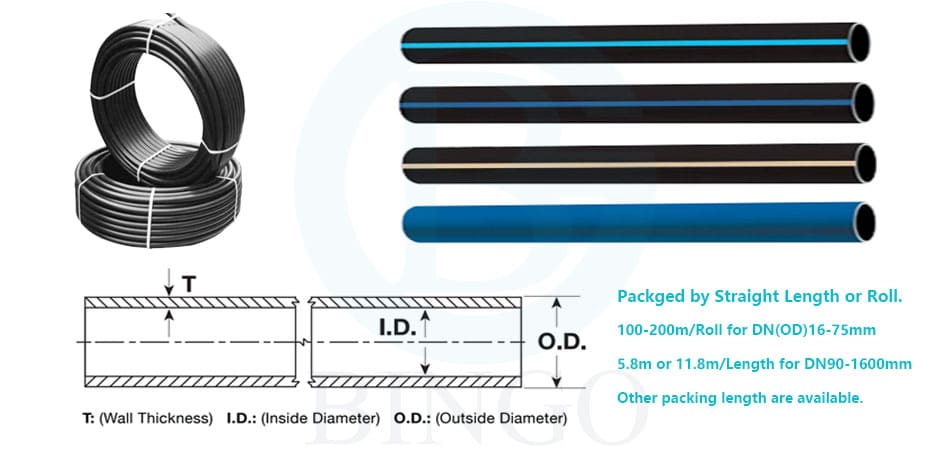

| Packing of HDPE Pipe for Cable Protection | |

|

|

| Packege with frame(Reel) | Packege without frame(Reel) to Save Space |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Description of High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings

Bingo Pipeline provide the solid smooth wall, large diameter HDPE pipes for cable protection in a wide variety of types and sizes, which are continuously extruded in lengths of up 200 meters, and smaller diameter even up to 2.5km.

Bingo HDPE cable protection solutions ensure undisrupted power transmission and protection for electrical, telecommunication and data cables, fiber optic cable, offering peace of mind with reliable and efficient overground, underground and underwater installations.

Certified and tested to national as well as international safety and quality standards, our piping solutions are idea for onshore, nearshore and offshore renewable energy projects, such as telecommunication, wind and solar farms.

Benefits of High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings

-Not susceptible to corrosion

- Moisture-proof and water-tight

- Immune to attack from insects

- Resists brittleness due to aging or cold weather

- Eliminates maintenance common to aerial networks

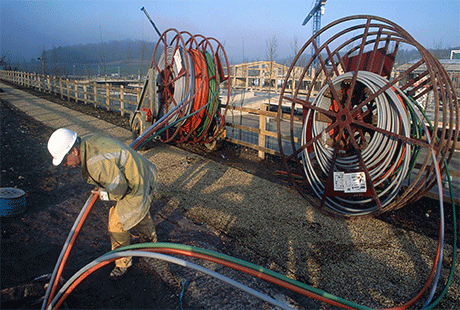

- Easy installation due to long lengths and high pull strength, HDPE pipe is the preferred material for HDD (Horizontal Directional Drilling), because of its long continuous lengths and high pull strength

- Low coefficient of friction allows easier long-distance cable pulls

- Follows trench contours, can be installed around obstacles underground

- Bends and flexes without breakage, even with ground heaves or shifts, over a wide range of temperatures

- High ductility resists damage during transportation, handling, and installation and retains impact resistance

Specifications of High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 1.0 | 17.98 | 0.6 | 18.72 | 0.61 | 18.72 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 1.2 | 22.48 | 0.8 | 23.39 | 0.76 | 23.39 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 1.5 | 28.77 | 1.0 | 29.94 | 0.97 | 29.94 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 2.0 | 35.76 | 1.2 | 37.43 | 1.21 | 37.43 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 2.4 | 44.91 | 2.0 | 45.76 | 1.52 | 46.79 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

DN20-75mm could be coiled, more than 90mm will be straight length by 5.8 or 11.8m per pcs.

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

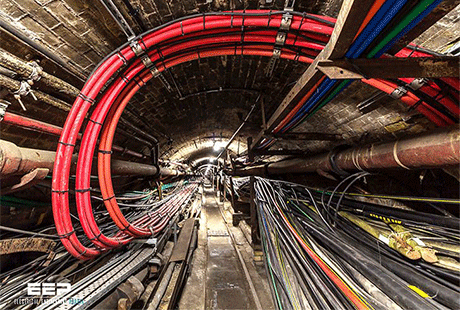

Application of High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings

- High density polyethylene (HDPE) conduit is the preferred material to house and protect electrical power and telecommunications cables, could be used for many fields.

- Power

- Low-voltage and medium voltage

- Site lighting

- Signal and control

- Fiber optic and communications

- Renewable energy(Solar and wind power projects)

- ITS(Intelligent transportation systems)

- SCADA(Supervisory Control and Data Acquisition)

|

|

| HDPE Pipes for Telecommunication | HDPE Pipes for Signal and Control |

|

|

| HDPE Pipes for Power Stations | HDPE Pipes for Fiber Pptic and Communications |

High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings

Packing of High Density Polyethylene (HDPE) Cable Protection Pipes and Fittings

| Packing of HDPE Pipe for Cable Protection | |

|

|

| Packege with frame(Reel) | Packege without frame(Reel) to Save Space |

| Small Dimaeter will be packaged by rolls, and for large diameter HDPE pipes will be packaged by length. | |

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español