Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

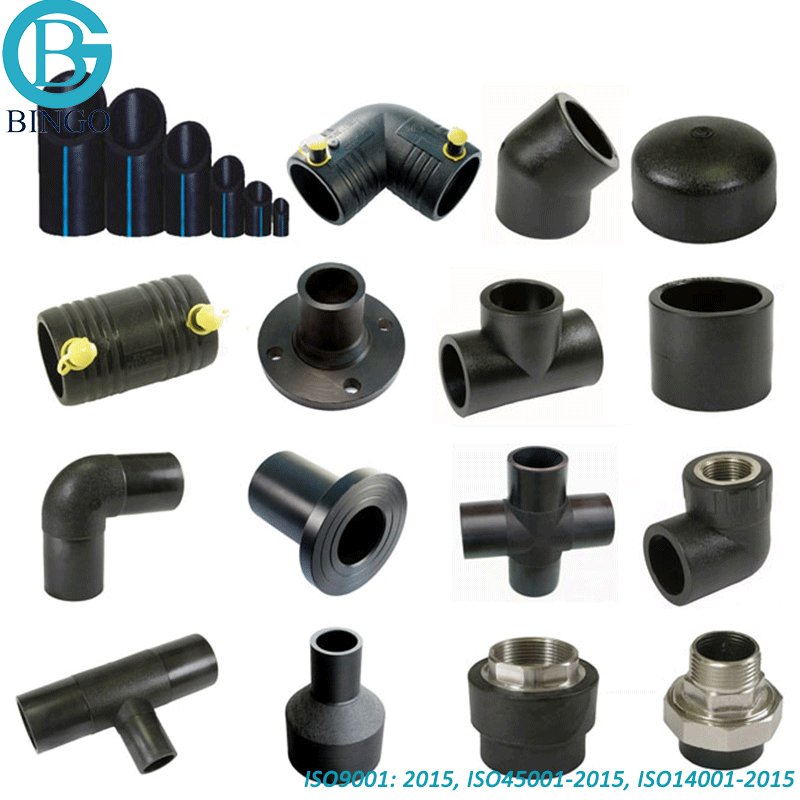

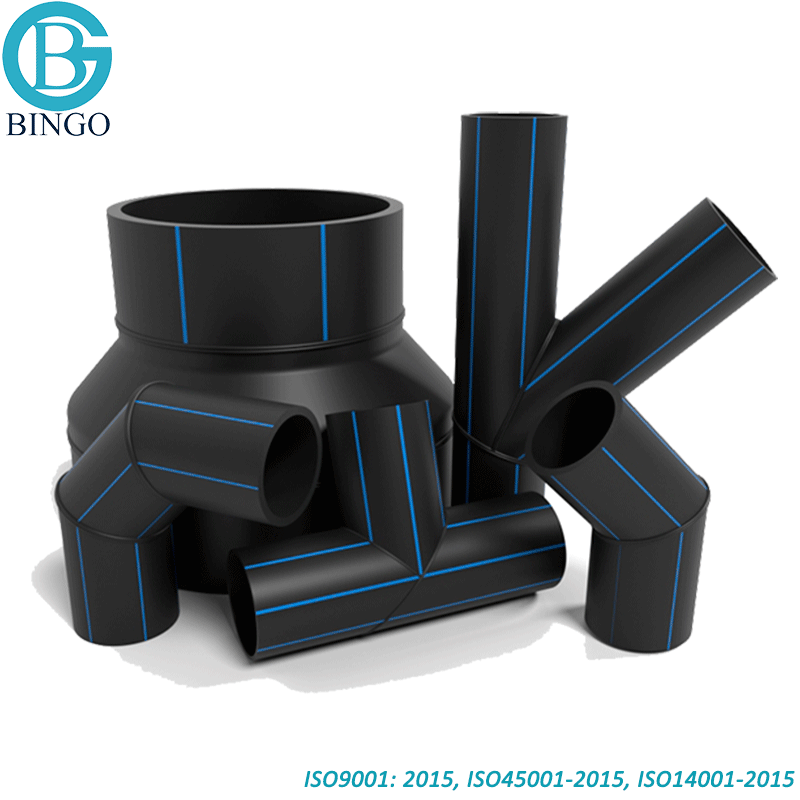

HDPE Fittings for Water and Gas

HDPE is a durable, flexible plastic. The insoluble material is weather-resistant, shock-resistant, and abrasion-resistant. HDPE is also highly affordable, created from petroleum under high heat. Rather than crack, HDPE is more likely to tear under pressure, reducing overall damage.

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: Packaged by cartons or bags

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High density polyethylene (HDPE) fittings for water and gas

| Products details information | |

| Product name | High density polyethylene (HDPE) fittings for water and gas |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Pressure Class | From PN10 to PN32 |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | water, oil and gas, mining, marine, chemical, industry, fish farming |

| Color | Black or Blue |

| Category | Butt fusion, Socket Fusion, EF fittings, Faricated Segment fittings, high pressure HDPE fittings... |

| Matching products | HDPE pipe fittings, Customized PE fittings, DI/ Steel backing ring flanges, Valves, water meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

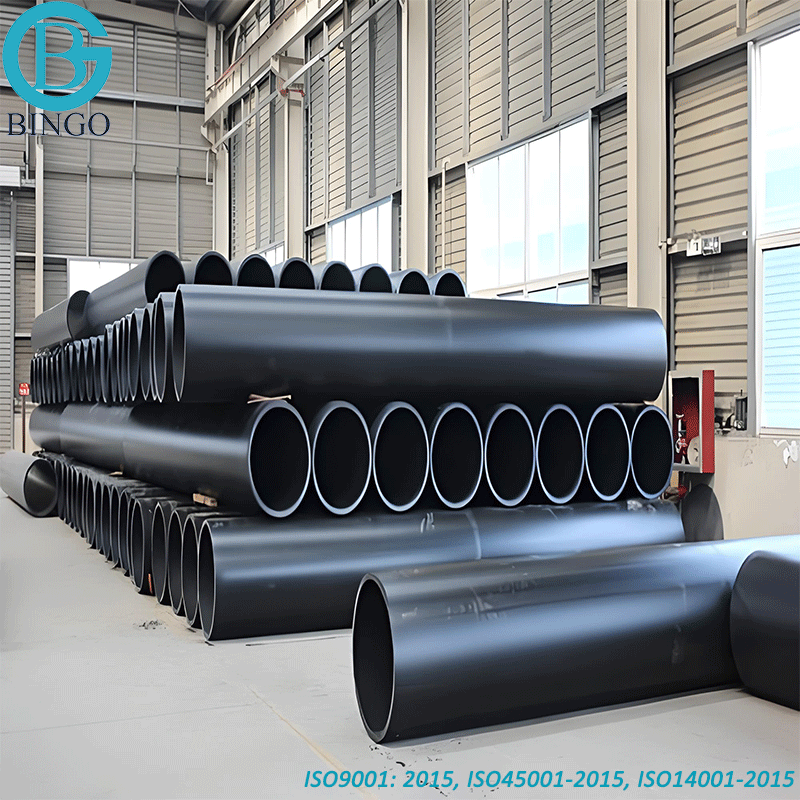

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High density polyethylene (HDPE) fittings for water and gas

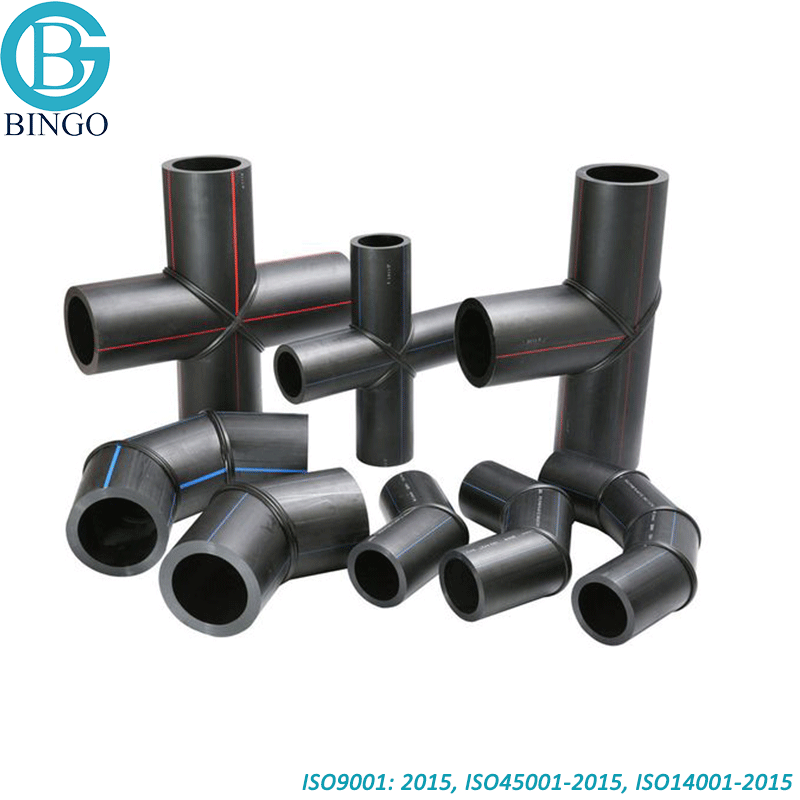

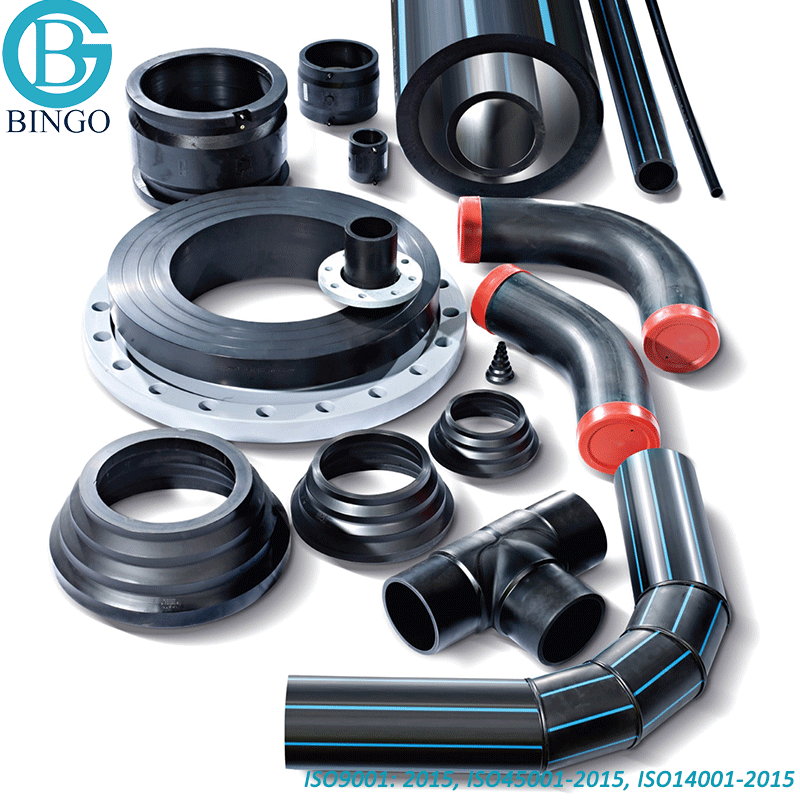

Bingo Pipeline provides customer HDPE fittings together with the HDPE pipes. We keep a variety of on-demand HDPE fittings in stock. Including the Socket fusion fittings, butt fusion fittings, electrofusion fittings, compression fittings, fabricated segments fittings and steel or metal backing rings, all related accessories from the diameter 20mm to 1200mm.

Below is the HDPE fittings for the pipelines we could provide:

1.Socket Fusion Fittings(OD20-110mm)

2.Threaded- Socket Fusion Fittings(OD20-110mm or 1/2''-4'')

3.Butt Fusion Fittings(OD63-1200mm)

4.Electrofusion Fittings(OD50-630mm)

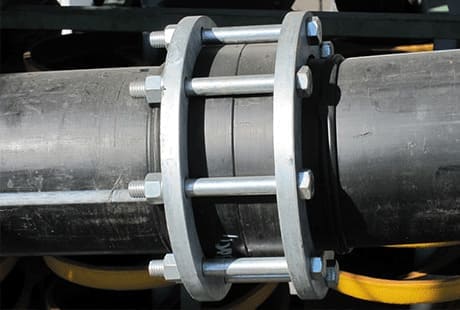

5.Flanges/Backing Ring(DN20-2000mm)

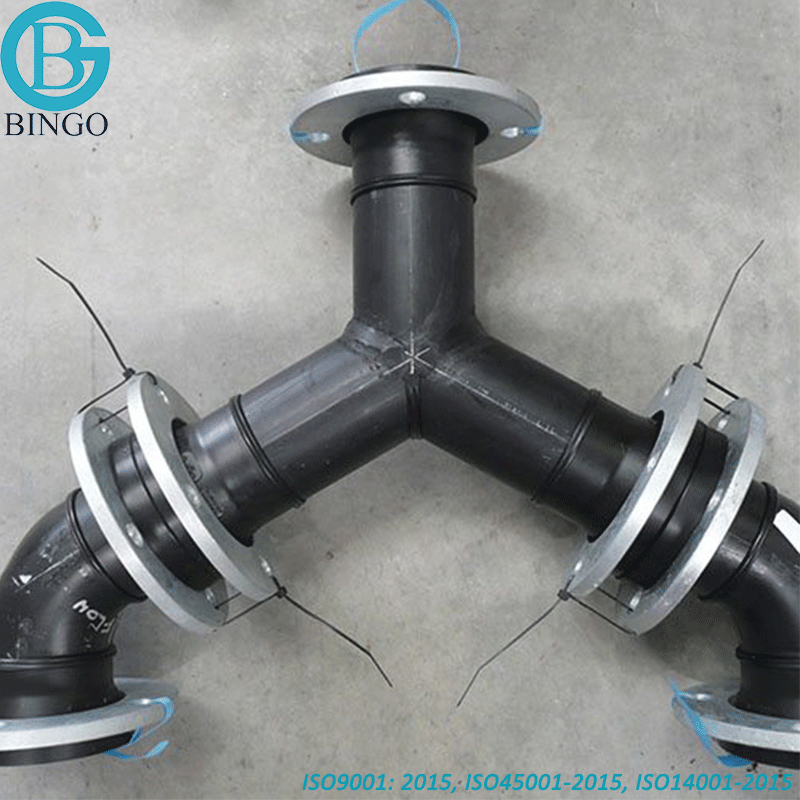

6.Fabricated Segments Fittings-Butt Fusion Ends(DN110-1200mm)

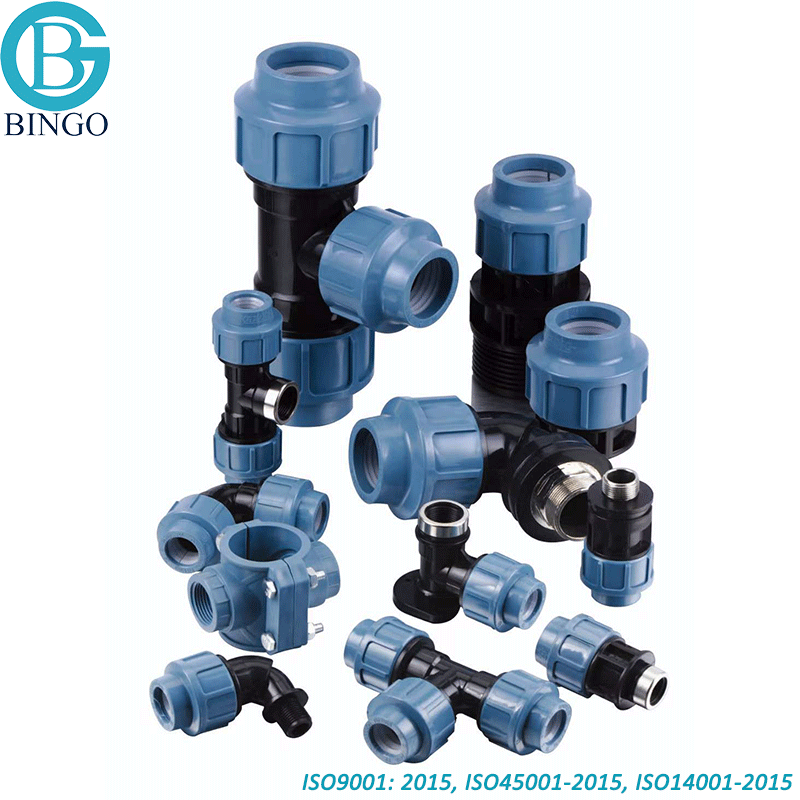

7.PP Compression Fittings(OD20-110mm)

8.Other related accessories and tools

9.Welding Machines(20-1400mm)

The benefits of High density polyethylene (HDPE) fittings for water and gas

Zero Leaks. PE fittings are heating joined together with the pipes by a heat fusion process that forms joints that are leak-free. This design eliminates the potential leak points every 20 feet which can occur with PVC & ductile iron pipe.

Corrosion & Chemical Resistant. PE fittings is non-conductive polymer & does not rust or corrode, assuring long service & effective use of municipal dollars.

Best For The Environment. PE is the safest, most environmentally friendly pipe material. The application of PE pipe for water distribution results in energy efficiency through reduced electric consumption. Using less energy results in a lower carbon footprint, & PE’s jointless fusion technology means it never releases toxins from sewage into the ground or potable water supply.

Lower Life Cycle Costs. Due to PE’s flexibility & jointless construction, installation costs are lower compared to other types of pipe. In addition, PE does not leak, which reduces repairs & maintenance costs simultaneously.

Best For Consumers. PE pipe and fitting’s outstanding performance means that consumers get the very best, cleanest water around. Other pipes leak, which means more electricity is needed to process & pump additional water into households. With PE pipe, there is no leakage. Therefore, less electricity is needed, which means consumers save on rising utility costs.

Lightweight & Flexible. PE is lightweight & does not require the use of heavy lifting equipment for installation. It reduces the need for fittings, is excellent in shifting soils & performs well in earthquake-prone areas. The pipe’s flexibility solves many unique problems that cannot be fixed with rigid concrete, PVC or ductile iron pipe.

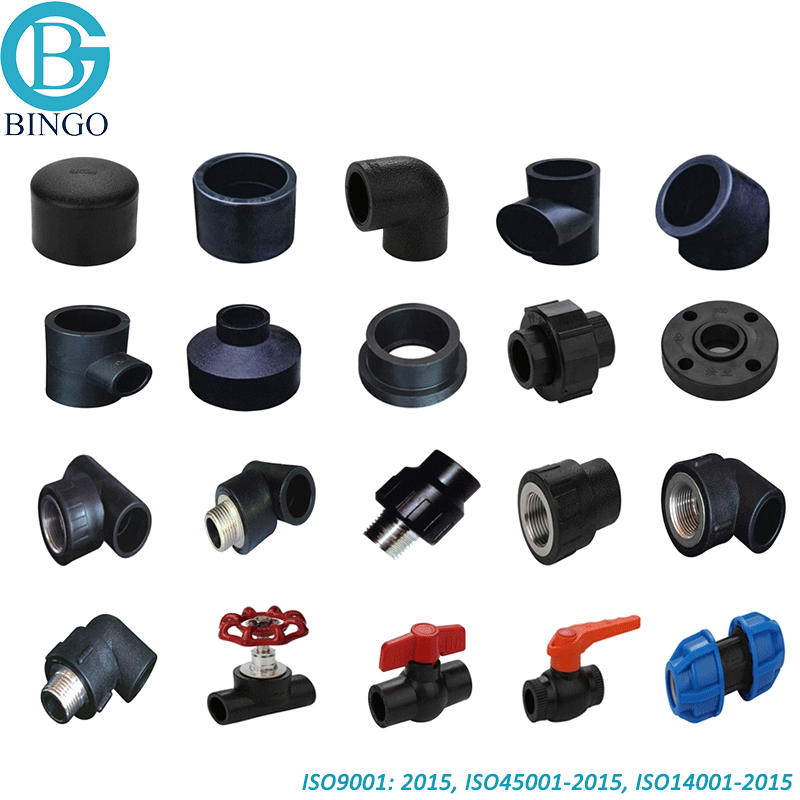

| HDPE Fittings for Water and Gas | ||

|

|

|

| HDPE Soclet Fusion Fittings | HDPE Butt Fusion Fittings | HDPE Electrofusion Fittings |

|

|

|

| PP Compression Fittings | High Pressure FIttings SDR6-SDR17 | HDPE Fabricated Segments Fittings |

Specification of High density polyethylene (HDPE) fittings for water and gas

| Item | Fittings Types | Specified Fittings | Diameter(mm) | Pressure Rates(PN-Bar) | Manufacturing Process |

| 1 | Socket Fusion Fittings | Coupler/Coupling | OD20-110mm | PN25, PN20, PN16, PN10 | Injection Molding |

| Reducer/ Reducing Coupler | |||||

| Tee | |||||

| Reducer Tee | |||||

| Stub End | |||||

| End Cap | |||||

| 45 deg elbow | PN16, PN10 | ||||

| 90 deg elbow | |||||

| 2 | Threaded- Socket Fusion Fittings | Female coupler | OD20-110mm 1/2'-4' | PN16, PN10 | Injection Molding |

| Male coupler | |||||

| Lifting Stop Valve | |||||

| Female Tee | OD20-63mm 1/2'-2' | PN16, PN10 | |||

| Male Tee | |||||

| Female Elbow 90 Deg | |||||

| PP Ball Valves | |||||

| Male Elbow 90 Deg | OD20-63mm 1/2'-2' | PN16, PN10 | |||

| Stop Valve | OD20-63mm | ||||

| Female Union | OD20-63mm 1/2'-2' | ||||

| 3 | Butt Fusion Fittings | Male Union | OD20-63mm 1/2'-2' | Injection Molding | |

| Reducer/ Reducing Coupler | OD75-630mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| Tee | OD63-630mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| Reducer Tee | OD75-630mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| 90 deg elbow | OD63-630mm | PN16, PN12.5, PN10 | |||

| 45 deg elbow | OD63-630mm | PN16, PN12.5, PN10 | |||

| 30 deg elbow | OD63-630mm | PN16, PN12.5, PN10 | |||

| 22.5 deg elbow | OD110-630mm | PN16, PN12.5, PN10 | |||

| End Cap | OD75-1200mm | PN25, PN20, PN16, PN12.5, PN10 | |||

| Cross Tee | OD63-315mm | PN16, PN12.5 | |||

| Reducer Cross Tee | OD90-315mm | PN16, PN12.5 | |||

| Stub End | OD50-630mm | PN16, PN12.5, PN10 | |||

| Lateral Tee(45 deg Tee) | OD63-160mm | PN16 | |||

| 4 | Electrofusion Fittings | EF Coupler/Coupling | OD50-630mm | PN16, PN12.5, PN10 | Injection Molding |

| EF Reducer/ Reducing Coupler | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF 45 deg elbow | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF 90 deg elbow | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF End Cap | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF Stub End | OD50-800mm | PN16, PN12.5, PN10 | |||

| EF Tee | OD50-630mm | PN16, PN12.5, PN10 | |||

| EF Reducer Tee | OD50-630mm | PN16, PN12.5, PN10 | |||

| 5 | Flanges/ Backing Ring | Blank/Blind-Metallic Material | DN20-2000mm | PN25, PN20, PN16, PN12.5, PN10, PN8 | Forged Casting |

| Plate Flange-Metallic Material | DN20-2000mm | PN25, PN20, PN16, PN12.5, PN10, PN8 | |||

| Blank/Blind-PP/PE Material | DN20-500mm | PN25, PN20, PN16, PN12.5, PN10, PN8 | Injection Molding | ||

| Plate Flange-PP/PE Material | DN20-500mm | PN25, PN20, PN16, PN12.5, PN10, PN8 | |||

| Rubber Seal Geskets | DN20-1200mm | - | |||

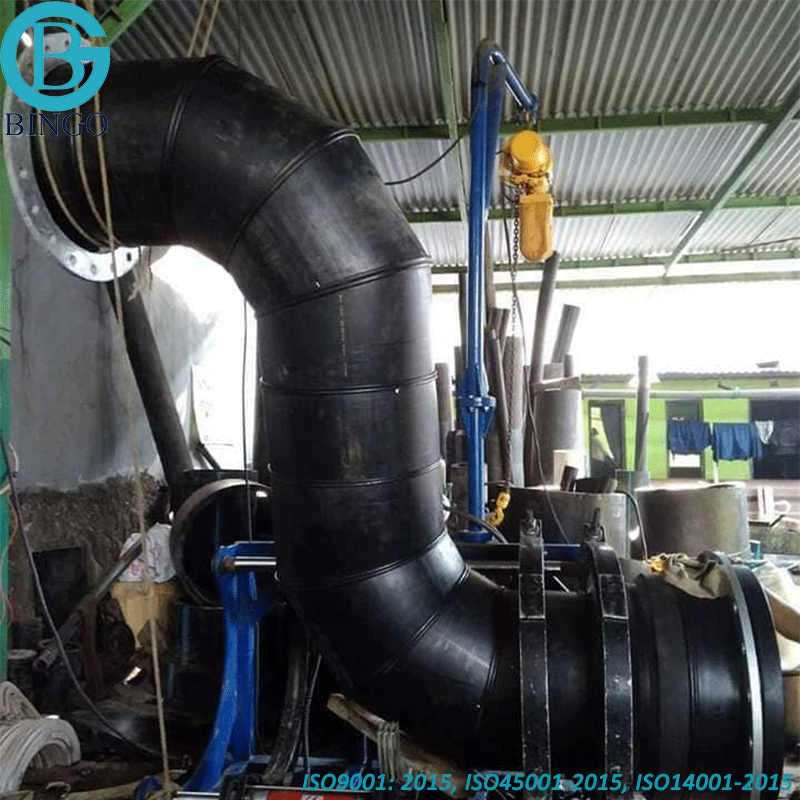

| 6 | Fabricated Segments Fittings-Butt Fusion Ends | Elbow: 11.25 Deg,22.5Deg 30Deg,45Deg 60Deg,90Deg and other required degrees | DN110-1200mm | PN16, PN12.5, PN10, PN8 | Segmented Fabrication |

| Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Reducer Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Lateral Tee(45 deg Tee) | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Cross Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Reducer Cross Tee | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Special-shaped S tube, etc | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| Sweep Bend R1.5D, R3D | DN110-1200mm | PN16, PN12.5, PN10, PN8 | |||

| 7 | PP Compression Fittings | Quick Coupling/Coupler | OD20-110mm | PN16, PN10 | Injection Molding |

| Quick Reducer/ Reducing Coupler | OD20-110mm | PN16, PN10 | |||

| Quick Tee | OD20-110mm | PN16, PN10 | |||

| Quick Reducer Tee | OD20-110mm | PN16, PN10 | |||

| Quick 45 deg elbow | OD20-110mm | PN16, PN10 | |||

| Quick 90 deg elbow | OD20-110mm | PN16, PN10 | |||

| Female coupler | OD20-110mm | PN16, PN10 | |||

| Male coupler | OD20-110mm | PN16, PN10 | |||

| Quick Female 90 deg elbow | OD20-110mm | PN16, PN10 | |||

| Quick Male 90 deg elbow | OD20-110mm | PN16, PN10 | |||

| Female Tee | OD20-110mm | PN16, PN10 | |||

| Male Tee | OD20-110mm | PN16, PN10 | |||

| Quick Flanges | OD20-110mm | PN16, PN10 | |||

| Ball Valves | OD20-63mm | PN16, PN10 | |||

| Saddle Clamp | OD20-250mm | PN16, PN10 | |||

| 8 | Customozed High Pressure PE fittings | Stub End | OD20-2000mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | CNC Lathe Process |

| Tee | OD200-900mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Mud Tee | OD200-900mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Concentric Reducer | OD110-1200mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Eccentric Reducer | OD110-1200mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| End Cap | OD80-1600mm | PN10, PN12.5, PN16. PN16, PN20, PN25, PN32 | |||

| Hollow Bar | OD80-1600mm | - | Extruded | ||

| Solid Bar | OD80-1600mm | - |

Other specifications have not been shown on our dimension chart, please CONTACT US (Mobile: +86 15515596408)for more information

Applications of High density polyethylene (HDPE) fittings for water and gas

We create regular HDPE fittings and customized fittings for a variety of uses.

- 1.Potable water networks

- 2.Oil and Gas Systems

- 3.Drinking water projects

- 4.Pressure water projects

- 5.Non-pressure water pipelines with the lower pressure number

- 6.Natural gas pipes as PE 80 Pipe or PE 100 Pipe

- 7.Petrolium area applications

- 8.Industrial area applications

- 9.Pool projects

- 10.Fish farm projects

- 11.Mining projects

- 12.Dredger piping projects for Sea Outfall drainage

- 13.HDPE Dredging Pipe

- 14.Drainage projects as Perforated HDPE Pipe

- 15.Non-Perforated HDPE pipe

- 16.Sewer pipelines

- 17.Natural spring water projects

- 18.High power cable protection projects

Please Contact us to Get More Projects Cases, Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

High density polyethylene (HDPE) fittings for water and gas

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español