Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

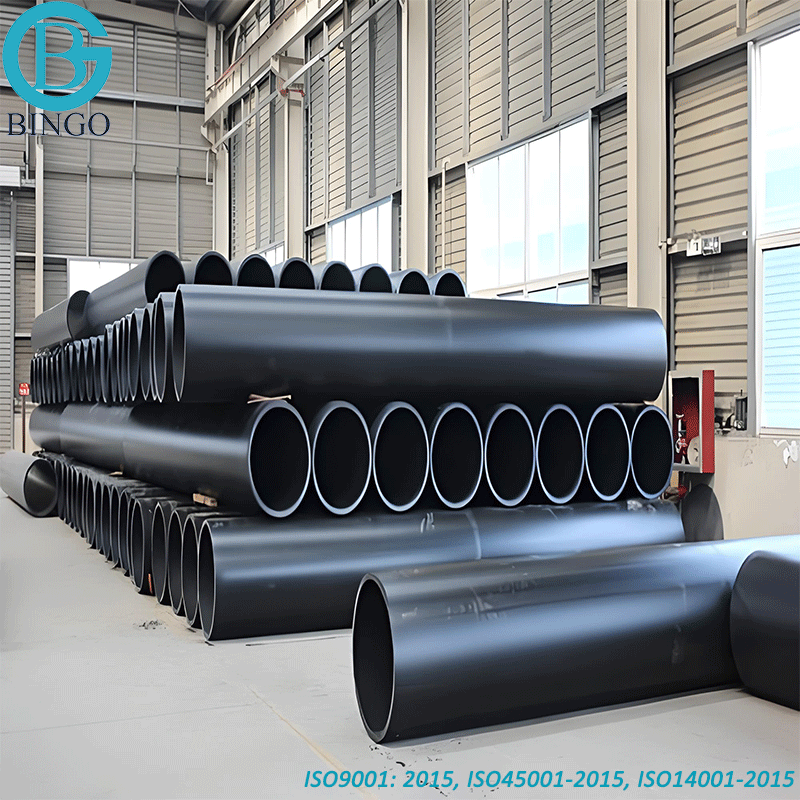

Co-Extruded White HDPE Pipes

PE100 pipe is manufactured with a highly reflective white exterior. This coating is extruded at the same time as the main pipe (co-extruded), forming an integral part of the pipe. This means more than 95% of the pipe is made of standard black PE material, with a thin white coating on the outside to reflect sunlight, reducing the amount of absorbed heat.

- 1.Delivery: 10-30 days depending on the total quantity.

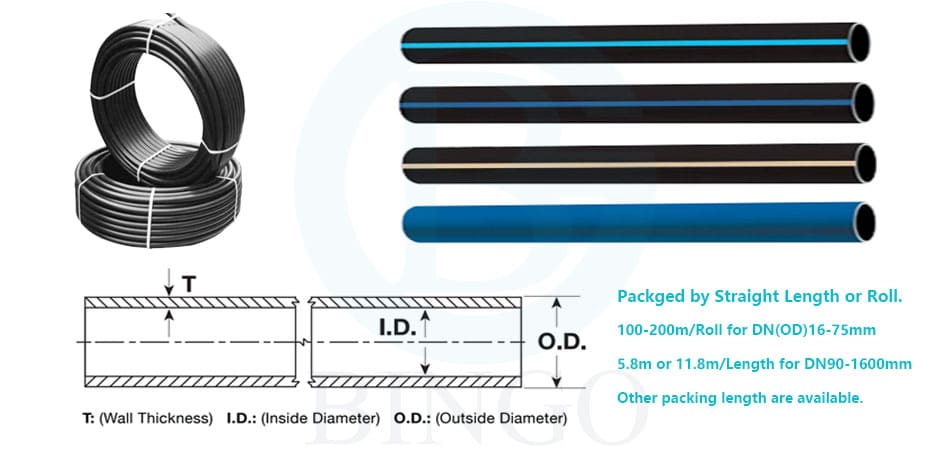

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of Co-Extruded White High Density Polyethylene (HDPE) Pipes

| Products details information | |

| Product name | Co-Extruded White High Density Polyethylene (HDPE) Pipes |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | Water Supply, Wastewater, Drainage, Mining, Chemical, Sewer... |

| Color | Black with blue stripes, black or others colors |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714... |

| Matching products | HDPE pipe fittings, PE flange, Water Pump, Customized Fittings, Fabricated fittings, Stainless Steel Flanges, Blind Flanges, Welding Machines and Tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of Co-Extruded White High Density Polyethylene (HDPE) Pipes

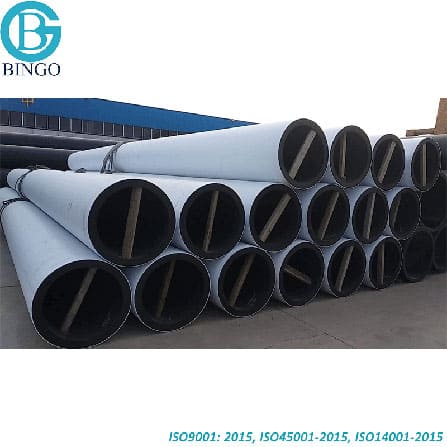

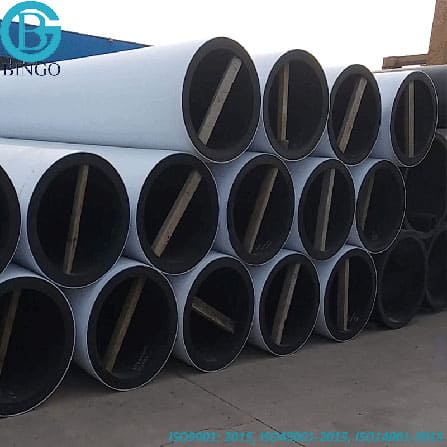

PE100 pipe is manufactured with a highly reflective white coating on the outside. This coating is extruded at the same time as the main pipe (co-extruded), forming an integral part of the pipe. This pipe is the ultimate solution for above ground applications including temporary water supply. which is a key part to reducing the effect of sunlight on the pipeline.

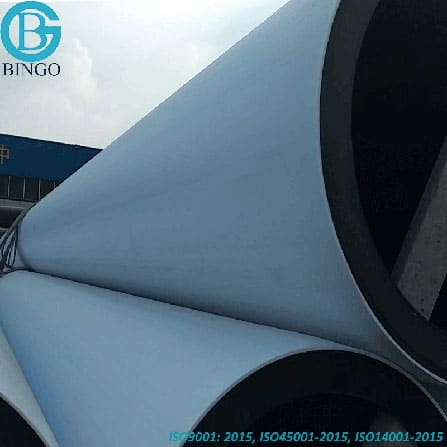

By the use of a highly reflective white material on the external skin, it could reduce the absorption of heat. The white material is extruded concurrently with the black pipe wall, forming an integral part of the pipe. Formulation of the white compound with HALS(Hindered Amine Light Stabilisers) and titanium dioxide increases the longevity of UV resistance in the outer layer.

Above ground polyethylene pipes will be absorb and disperse thermal energy via number mechanisms. Incoming solar radiation heats the pipes whilst re radiation, convection and conduction to the fluid conveyed will act to cool the pipes, Variation in the coming solar radiation intensity with time of day, could cover, latitude, altitude, season and pipeline orientation combine to be major determinants of the temperature, Wind velocity, ambient temperature, flow rate and nature of the conveyed fluid are also variables acting to influence pipe wall temperature.

Co-extruded pipe technology has been around for years but had typically been more expensive than standard black poly pipe, Bingo has invested in new state of the art extrusion machinery that can produce to-extruded PE pipe very efficiently. This means that the cost of co-extruded pipes are not much more than standard black HDPE pipes.

Extensive testing has demonstrated that solar radiation has substantial and predictably less effect on co-extruded white pipes as opposed to conventional black polyethylene pipe under the same conditions.

In all respects, co-extruded white pipes matches or exceeds the performance requirements of ISO4427, EN12201 pipes for pressure applications.

By limiting the surface temperature of above ground polyethylene pipelines, a thinner walled pipe can be used then would otherwise be required in a given application.

Much of this complexity can be reduced by considering that any pipes design much accommodate the most arduous environmental conditions to be encountered. For polyethylene pipelines, this requires the estimation of long term temperature conditions in the pipe, especially during summer.

Test of conventional black polyethylene pipes and the white co- extruded HDPE by an independent laboratory had confirmed lower radiation absorption, resulting in substantial reductions in temperature with this material.

Absorptance, the ratio of the amount of radiation absorbed by a surface to the amount of radiation incident upon it.

| Radiation Absorption | |

| Standard Black PE Pipe | 96% |

| Co-extruded white PE pipe | 42% |

Co-extruded white PE pipes maintain a lower operating temperature to reduce the thermal rerating requirement of above ground pipelines.

White HDPE pipe – sizes below can be made in SDR7.4, SDR9, SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33, SDR41

Advantages of Co-Extruded White High Density Polyethylene (HDPE) Pipes

Co-extruded white HDPE pipe is the ultimate solution for above ground applications including temporary water supply, and offers the following advantages over black polyethylene pipe:

Full white coating to minimize solar heating of pipe and contents; testing has demonstrated more than 50% reduction.

Ultra-violet (UV) resistance

Lower pressure rating can be used as lower operating temperature reduces the need to allow for pressure de-rating, enabling thinner wall pipe to be used. This provides cost savings in both material and through increased flow rates.

Reduced thermal expansion / contraction mean less need to ‘snake’ pipelines

Flexibility allows pipeline to accommodate topographical features.

Excellent solution for above ground applications including temporary water supply.

Twin wall pipe, co-ex or co ex pipe, or ‘double skinned pipe’ means that the white material is extruded at the same time as the black material, bonding the two together.

Manufactured to AS/NZS 4130, ISO4427, EN12201 Polyethylene – PE – pipes for pressure applications”

Co-extruded white HDPE Pipe can be joined with electro fusion fittings, butt welding equipment or compression fittings.

High pipes stiffness. Great resistance to collapse under vacuum effect.

Specifications of Co-Extruded White High Density Polyethylene (HDPE) Pipes

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 13.6 | 2.3 | 15.12 | 2.0 | 15.76 | 1.5 | 16.88 | 1.2 | 17.51 | 1.0 | 17.98 | 0.6 | 18.72 | 0.61 | 18.72 | 20 |

| 25 | 0.98 | 3.5 | 17.60 | 3.0 | 18.64 | 2.3 | 20.12 | 2.0 | 20.76 | 1.5 | 21.88 | 1.2 | 22.48 | 0.8 | 23.39 | 0.76 | 23.39 | 25 |

| 32 | 1.26 | 4.4 | 22.70 | 3.6 | 24.37 | 3.0 | 25.64 | 2.4 | 26.91 | 2.0 | 27.76 | 1.5 | 28.77 | 1.0 | 29.94 | 0.97 | 29.94 | 32 |

| 40 | 1.57 | 5.5 | 28.30 | 4.5 | 30.46 | 3.7 | 32.16 | 3.0 | 33.64 | 2.4 | 34.91 | 2.0 | 35.76 | 1.2 | 37.43 | 1.21 | 37.43 | 40 |

| 50 | 1.97 | 6.9 | 35.40 | 5.6 | 38.13 | 4.6 | 40.25 | 3.7 | 42.16 | 3.0 | 43.64 | 2.4 | 44.91 | 2.0 | 45.76 | 1.52 | 46.79 | 50 |

| 63 | 2.48 | 8.6 | 44.80 | 7.1 | 47.95 | 5.8 | 50.70 | 4.7 | 53.04 | 3.8 | 54.94 | 3.0 | 56.64 | 2.5 | 57.70 | 1.91 | 58.95 | 63 |

| 75 | 2.95 | 10.3 | 53.20 | 8.4 | 57.19 | 6.8 | 60.58 | 5.6 | 63.13 | 4.5 | 65.46 | 3.6 | 67.37 | 2.9 | 68.85 | 2.27 | 70.18 | 75 |

| 90 | 3.54 | 12.3 | 63.90 | 10.1 | 68.59 | 8.2 | 72.62 | 6.7 | 75.80 | 5.4 | 78.55 | 4.3 | 80.88 | 3.5 | 82.58 | 2.73 | 84.22 | 90 |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Application of Co-Extruded White High Density Polyethylene (HDPE) Pipes

- HDPE pipes are used above ground

- Mining site

- Irrigation pipes laid on the farmland

- Temporary water treatment above ground

- Areas not suitable for excavation

- Chemical plant

- Oil processing plant

- Marine pipes on sea

Co-Extruded White High Density Polyethylene (HDPE) Pipes

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español