Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

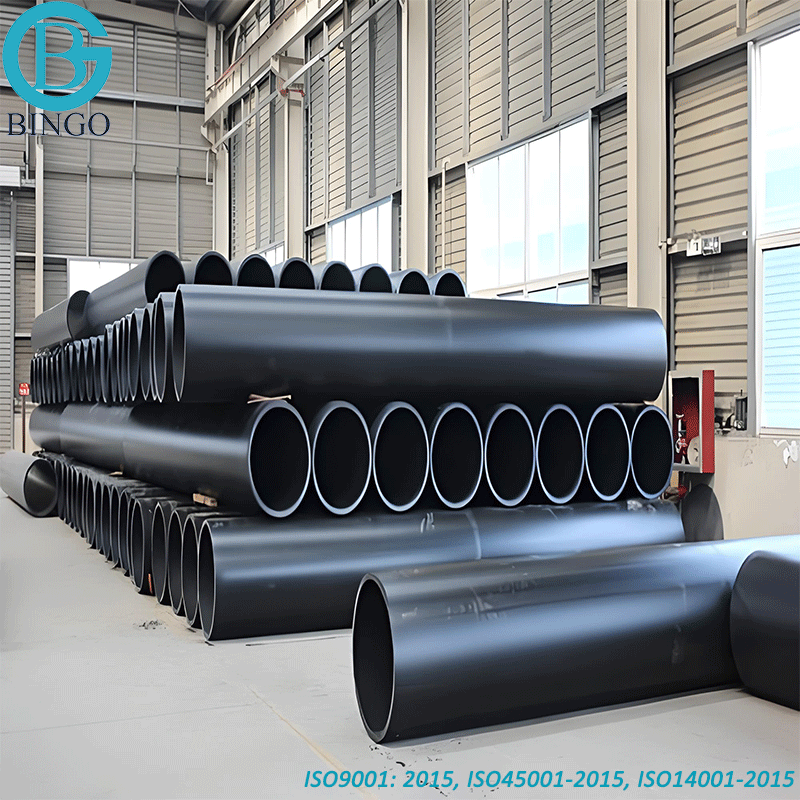

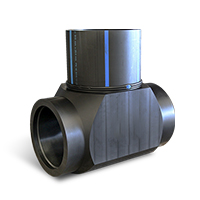

HDPE Pipes and Fittings for Drinking Water

Bingo high-performance high-density polyethylene water pressure pipes are suitable for municipal and industrial transmission systems for potable water, sewer, drain, mining, irrigation, and reclaimed water.

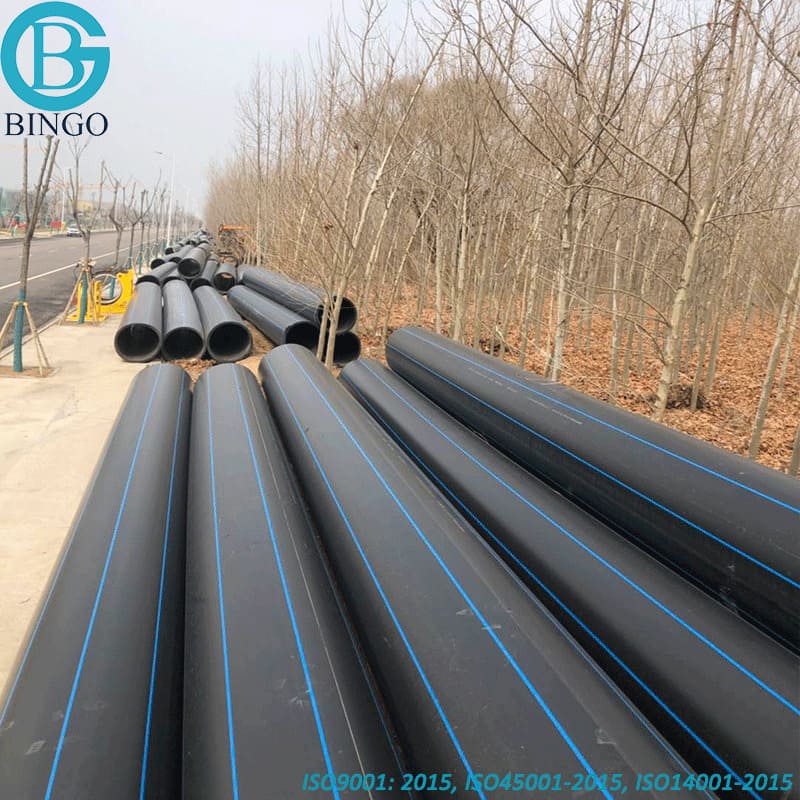

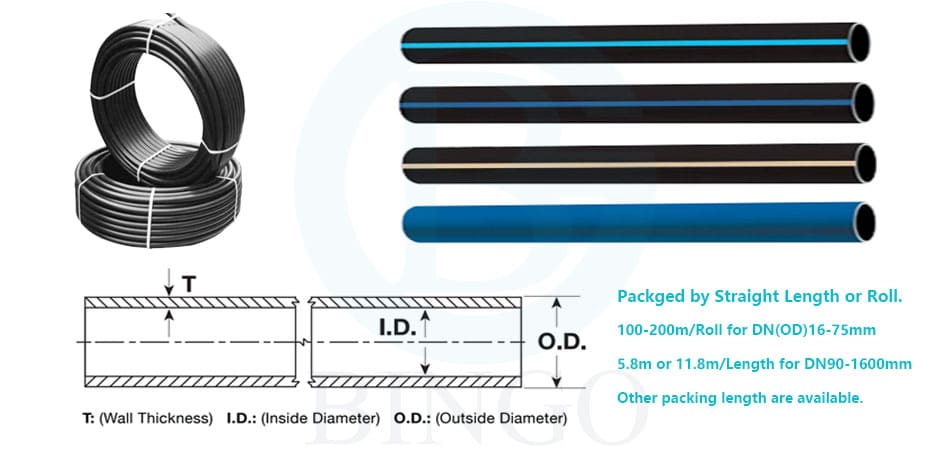

- 1.Delivery: 10-30 days depending on the total quantity.

- 2.Packing: 11.8m or 5.8m/ Pcs for straight, 100-200m by coils for DN20-90mm.

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings

| Products details information | |

| Product name | High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings |

| Brand | Bingo pipeline(Customer brand is available) |

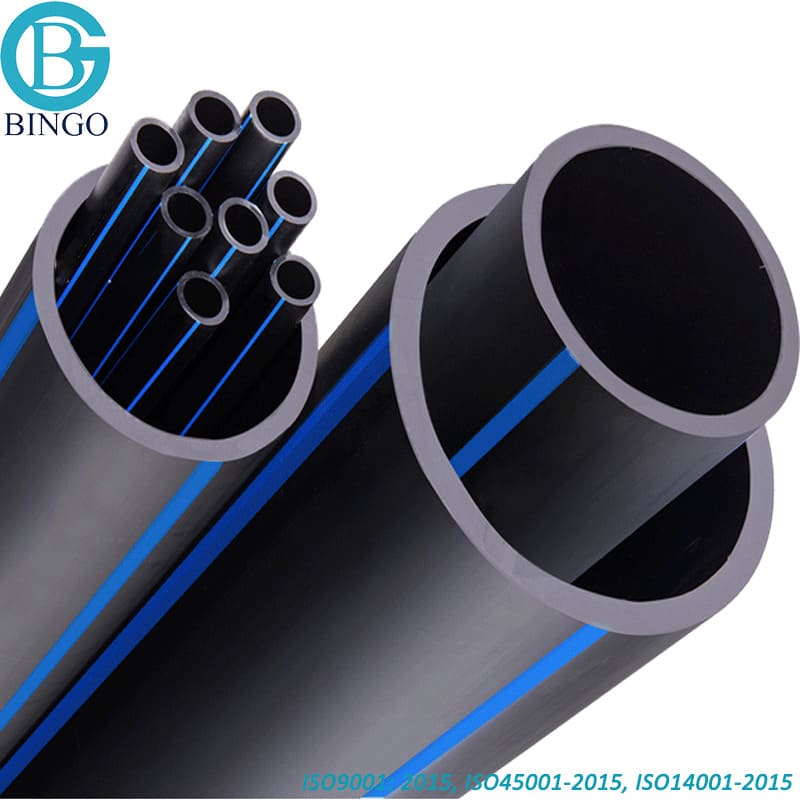

| Dia Ranges | DN20-2000mm(1/2 inch-80 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | drinking water, fresh water, drainage, mining, dredging, marine, industry, chemical... |

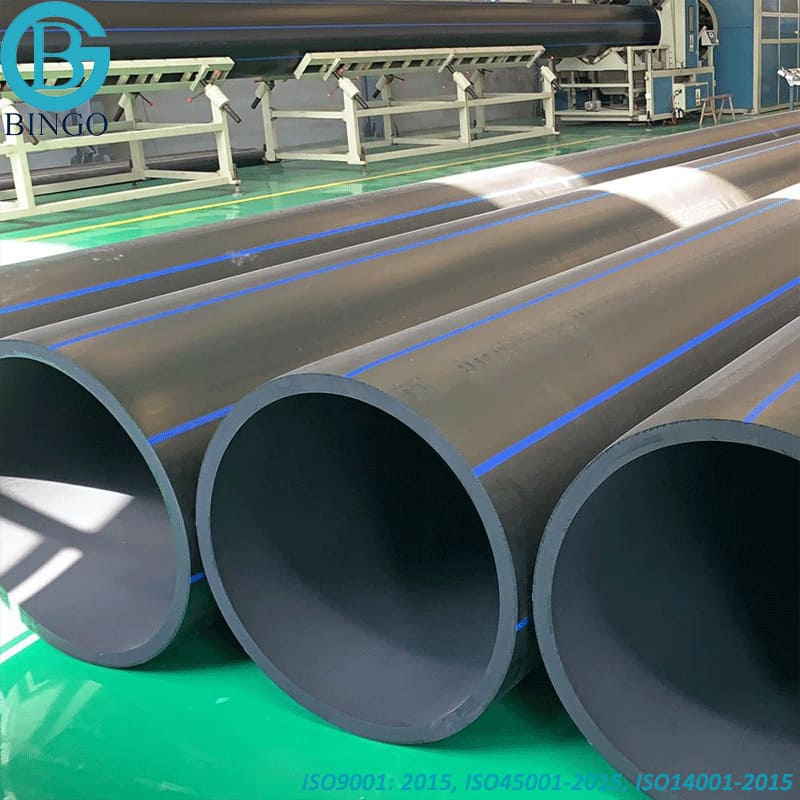

| Color | Black with blue stripes, blue or others colors |

| Standards | ISO 4427,EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, DIPS, ASTM F714... |

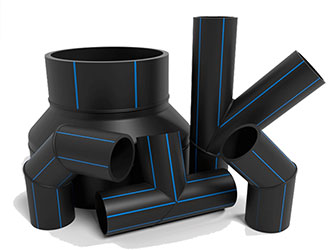

| Matching products | HDPE pipe fittings, Customized PE fittigns,DI/ Steel backing ring flanges, Valves, water meter, flow gauge, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings

Bingo HDPE pipe is the ideal piping solution for public and private potable water systems. HDPE pipe features a service life of over 100 years and has the versatility to perform in a variety of conditions. HDPE pipe provides a logical, low-maintenance investment in municipal and private potable water applications.

Bingo HDPE pipe’s long service life and low maintenance costs, coupled with its’ ability to be installed with a variety of trench-less technologies leads to HDPE pipe having the lowest life cycle costs of any potable water piping system.

| HDPE Pipe for Water | |||

|

|

|

|

Benefits of High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings

Bingo HDPE pipe is well-suited for potable water supply applications. Beneficial properties of Bingo HDPE piping systems include:

Leak-free Fused Joints. Fused joints eliminate potential leak points and reduce installation time.

Chemical Resistance. Studies show that HPDE pipe will not corrode or tuberculate, maintaining flow velocities over the life span of the system.

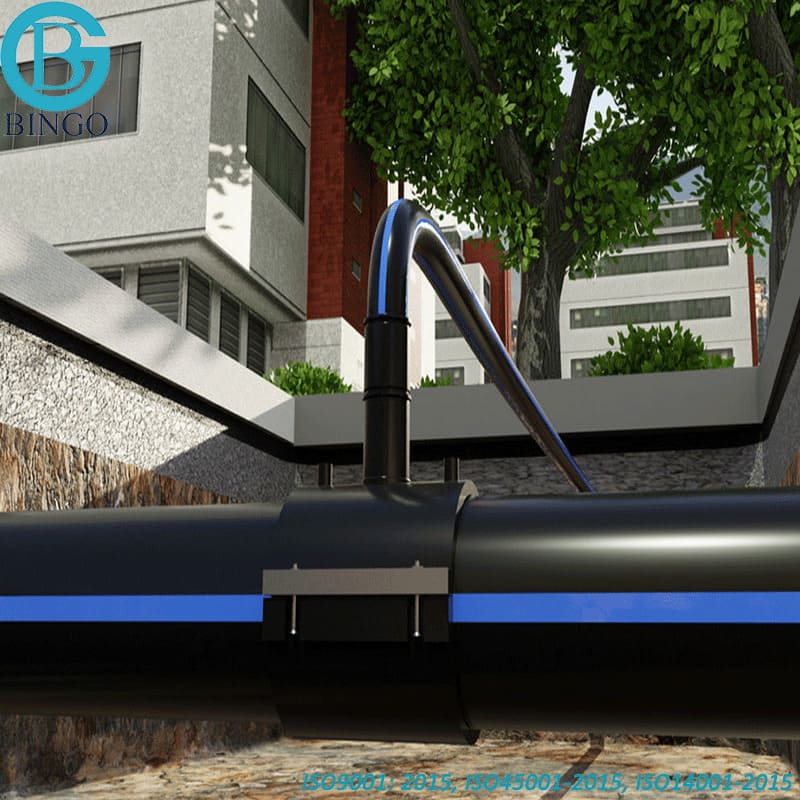

Durability and Flexibility. HDPE pipe is a more durable and flexible pipe material with a bend radius up to 20 times the pipe diameter. This allows the HDPE pipe to conform to an imperfect installation path without the need to add costly fittings and excessive pipe joints.

Extreme Surge Tolerance. HDPE pipes are the most resistant to surge and fatigue of any potable water piping systems. HDPE pipe can handle much higher flow velocities which result in lower pressure surges compared to other potable water piping systems.

Temperature Resistance. HDPE pipe can handle fluid and environmental temperatures ranging from -40°F to 140°F, making HDPE water pipe suitable for use with hot or cold water in many different environments.

Installation. HDPE pipe is cheaper to install than other potable water piping systems. Could be installed with trench-less technologies (directional drilling, pipe bursting, slip-lining, and compression fit lining), making HDPE pipe the most commonly used piping material for trenchless installations, greatly reduce the amount of construction restoration, leading to a cost savings up to 65%.

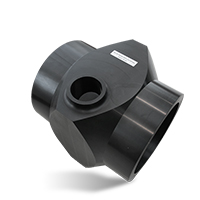

Jointing methods that fit your multiple requirements

We provide complete system solutions with engineer support based on 20 years of experience in HDPE pipes projects worldwide. All pipes section are supplied with flanges connections and blind flanges to facilitate a quick assembly and increase the overall safety of your installation. To fit your unique projects requirements. Our HDPE pipes can be jointed using several methods:

Electrofusion welding

Butt fusion welding

Socket fusion welding

Extrusion welding

Saddle welding

Flange connection

Quick fittings connection

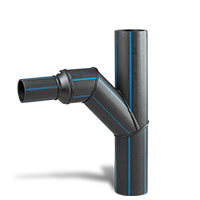

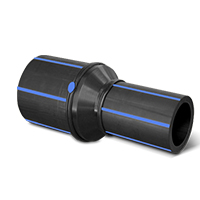

We have completed HDPE Fittings and Welding Machine, tools to completed with our HDPE Pipe for your construction, One-stop supply, to meet your different requriement, save your cost and time, Please visit our HDPE Fittings Category and Welding Machine Category, Contact Us To get more details.

Please Contact us to Get More Details, Send Email: sales@bingopipes.com. or Mobile:(WhatsApp): +86 155 15596408.

Specifications of High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings

ISO 4427-2: Plastics piping systems. Polyethylene pipes & fittings for water supply – Part 2: Pipes

EN 12201-2: Plastics piping systems for water supply – Polyethylene – Part 2: Pipes

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Min T.W. (mm) | Nominal Size DN (mm) |

| 20 | 0.79 | 3.0 | 2.3 | 2.0 | 1.5 | 1.2 | 1.0 | 0.6 | 0.61 | 20 |

| 25 | 0.98 | 3.5 | 3.0 | 2.3 | 2.0 | 1.5 | 1.2 | 0.8 | 0.76 | 25 |

| 32 | 1.26 | 4.4 | 3.6 | 3.0 | 2.4 | 2.0 | 1.5 | 1.0 | 0.97 | 32 |

| 40 | 1.57 | 5.5 | 4.5 | 3.7 | 3.0 | 2.4 | 2.0 | 1.2 | 1.21 | 40 |

| 50 | 1.97 | 6.9 | 5.6 | 4.6 | 3.7 | 3.0 | 2.4 | 2.0 | 1.52 | 50 |

| 63 | 2.48 | 8.6 | 7.1 | 5.8 | 4.7 | 3.8 | 3.0 | 2.5 | 1.91 | 63 |

| 75 | 2.95 | 10.3 | 8.4 | 6.8 | 5.6 | 4.5 | 3.6 | 2.9 | 2.27 | 75 |

| 90 | 3.54 | 12.3 | 10.1 | 8.2 | 6.7 | 5.4 | 4.3 | 3.5 | 2.73 | 90 |

| 110 | 4.33 | 15.1 | 12.3 | 10.0 | 8.1 | 6.6 | 5.3 | 4.2 | 3.33 | 110 |

| 125 | 4.92 | 17.1 | 14.0 | 11.4 | 9.2 | 7.4 | 6.0 | 4.8 | 3.79 | 125 |

| 140 | 5.51 | 19.2 | 15.7 | 12.7 | 10.3 | 8.3 | 6.7 | 5.4 | 4.24 | 140 |

| 160 | 6.30 | 21.9 | 17.9 | 14.6 | 11.8 | 9.5 | 7.7 | 6.2 | 4.85 | 160 |

| 180 | 7.09 | 24.6 | 20.1 | 16.4 | 13.3 | 10.7 | 8.6 | 6.9 | 5.45 | 180 |

| 200 | 7.87 | 27.4 | 22.4 | 18.2 | 14.7 | 11.9 | 9.6 | 7.7 | 6.06 | 200 |

| 225 | 8.86 | 30.8 | 25.2 | 20.5 | 16.6 | 13.4 | 10.8 | 8.6 | 6.82 | 225 |

| 250 | 9.84 | 34.2 | 27.9 | 22.7 | 18.4 | 14.8 | 11.9 | 9.6 | 7.58 | 250 |

| 280 | 11.02 | 38.3 | 31.3 | 25.4 | 20.6 | 16.6 | 13.4 | 10.7 | 8.48 | 280 |

| 315 | 12.40 | 43.1 | 35.2 | 28.6 | 23.2 | 18.7 | 15.0 | 12.1 | 9.70 | 315 |

| 355 | 13.98 | 48.5 | 39.7 | 32.2 | 26.1 | 21.1 | 16.9 | 13.6 | 10.90 | 355 |

| 400 | 15.75 | 54.7 | 44.7 | 36.3 | 29.4 | 23.7 | 19.1 | 15.3 | 12.30 | 400 |

| 450 | 17.72 | 61.5 | 50.3 | 40.9 | 33.1 | 26.7 | 21.5 | 17.2 | 13.80 | 450 |

| 500 | 19.69 | 67.6 | 55.8 | 45.4 | 36.8 | 29.7 | 23.9 | 19.1 | 15.30 | 500 |

| 560 | 22.05 | 75.7 | 62.5 | 50.8 | 41.2 | 33.2 | 26.7 | 21.4 | 17.20 | 560 |

| 630 | 24.80 | 85.1 | 70.3 | 57.2 | 46.3 | 37.4 | 30.0 | 24.1 | 19.30 | 630 |

| 710 | 27.95 | 95.9 | 79.3 | 64.5 | 52.2 | 42.1 | 33.9 | 27.2 | 21.80 | 710 |

| 800 | 31.50 | 89.3 | 72.6 | 58.8 | 47.4 | 38.1 | 30.6 | 24.50 | 800 | |

| 900 | 35.43 | 81.7 | 66.2 | 53.3 | 42.9 | 34.4 | 27.60 | 900 | ||

| 1000 | 39.37 | 90.2 | 72.5 | 59.3 | 47.7 | 38.2 | 30.60 | 1000 | ||

| 1200 | 47.24 | 88.2 | 67.9 | 57.2 | 45.9 | 36.70 | 1200 | |||

| 1400 | 55.12 | 102.9 | 82.4 | 66.7 | 53.5 | 42.90 | 1400 | |||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||

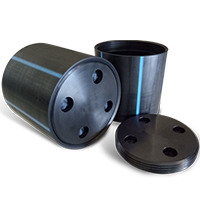

High Density Polyethylene (HDPE) Pipes and Fittings Series for Drinking Water Pipes and Fittings

Please find below HDPE pipes for different applications in accordance with different standards. Please clinck to view detailed products and specifications.

| HDPE Products Series | ||||

| HDPE Pipe | Standatd | Photo | ||

| Size | DN20-2000mm(1/2 inch-80 inch) |  |

||

| HDPE Pipe for Water | HDPE Pipe for Drinking Water | |||

| HDPE Pipe for Industry | ||||

| HDPE Pipe for Mining | ||||

| HDPE Pipe for Drainage | ||||

| HDPE Pipe for Marine | ||||

| HDPE Pipe for Fish Farming | ||||

| HDPE Pipe for Irrigation | ||||

| HDPE Pipe for Cable Protection | ||||

| Standatd | ISO 4427 | |||

| EN12201 | ||||

| AS/NZS4130 | ||||

| ASTM 3035 | ||||

| DIN8074 | ||||

| GOST18599 | ||||

| DIPS | ||||

| ASTM F714 | ||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Applications of High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings

- 1.Offering HDPE Water Supply Systems

- 2.HDPE Pipe for Water Distribution System

- 3.HDPE pipe of potable water supply

- 4.HDPE water purifier, treatment water plants, water supply pipelines

- 5.HDPE and PVC pipelines for the transport of water

- 6.HDPE Irrigation & Water Systems

- 7.Town water system

- 8.Civil construction for water supply

|

|

| HDPE Pipes for Process Water | HDPE Pipes for Municipal Water & Sewer |

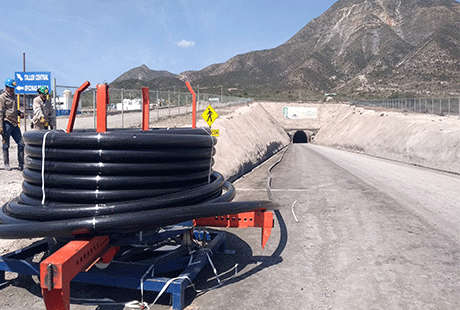

|

|

| HDPE Pipes for Water Transportation | HDPE Pipes for Sewerage |

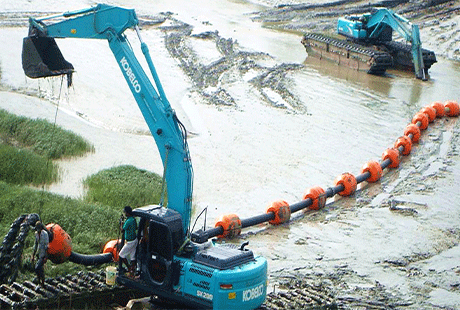

|

|

| HDPE Pipes for Mining Projects | HDPE Pipes for Slurry Dredging |

Please Contact us to Get More Projects Cases, Send Email: sales@bingopipes.com. or Mobile:(WhatsApp): +86 155 15596408.

High Density Polyethylene (HDPE) Drinking Water Pipes and Fittings

-

- Below are the HDPE Pipe specification, Pressure rating, Thickness, Dimension chart in different standard for water and fuels gas application for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@bingopipes.com. Mobile(WhatsApp): +86 155 15596408.

- ISO4427 HDPE pipes Metric Size and Dimension DownLoad

- EN 12201-2-2011 Pipe Series DownLoad

- ASTM 3035 and ASTM F 714 Iron Pipe Size (IPS) and Dimension Data Dimension in millimeter DownLoad

- ASTM 3035 and ASTM F 714 Iron Pipe Size (IPS) and Dimension Data in Inch size DownLoad

- Ductile Iron Pipe Size (DIPS) and Dimension Data DownLoad

- ASNZS 4130-2009 Pipe Series Standard Dimension Ratios (SDRs) DownLoad

- ISO4437-2 Plastics piping systems for the supply of gaseous fuels-Polyethylene (PE)- Part 2 Pipes DownLoad

- EN1555-2 Plastics piping systems for the supply of gaseous fuels-Polyethylene (PE)- Part 2 Pipes DownLoad

- ASTM D2513 IPS HDPE Gas Distribution Pipe DownLoad

- ASNZS 4130 Series Pipes -Gas(Nominal Outside Diameter Series) DownLoad

| Customized PE100 SDR33-SDR7.4 HDPE Spool Pipe & Fittings | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

||||

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@bingopipes.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español