Products+

Latest Products

Contact Us

-

- Henan Bingo Pipeline Co., Ltd.

- Mobile: +86 15515596408(WhatsApp)

- Email: sales@bingopipes.com

- Add: R102, No. 123 Zhongyuan Middle Road, Zhongyuan District, Zhengzhou City, Henan Province, China

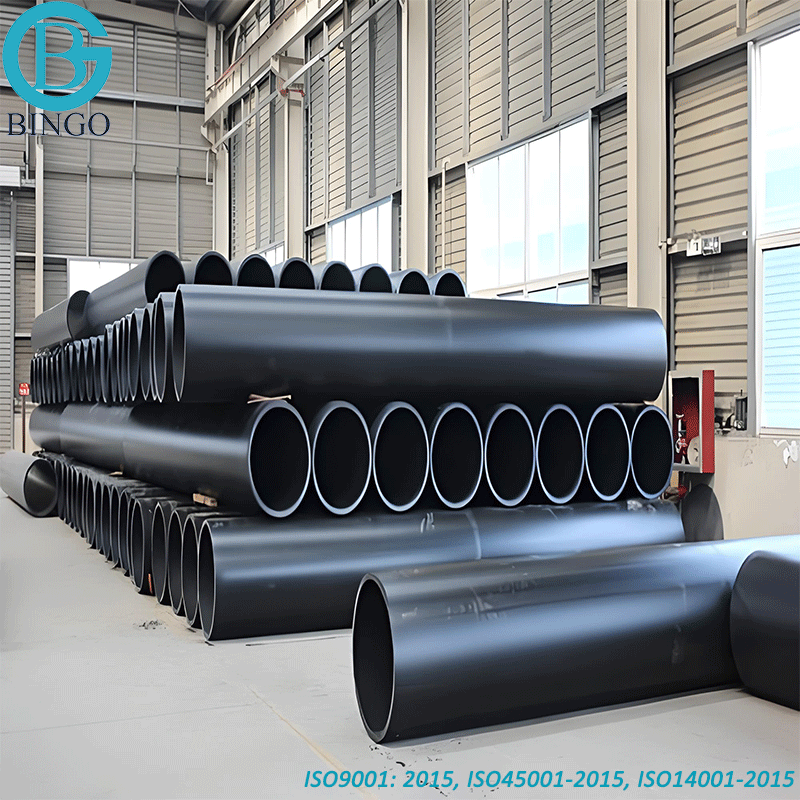

HDPE Pipes and Fittings for Dredging

HDPE dredging pipe is widely used in dredging projects, waterways, wetlands, land reclamation, dewatering of sludge, lake trout and lake restoration, flooding the river or Dredging PE Pipes wamp, and many other applications used cries.

- 1.Delivery: 10-30 days depending on the total quantity.

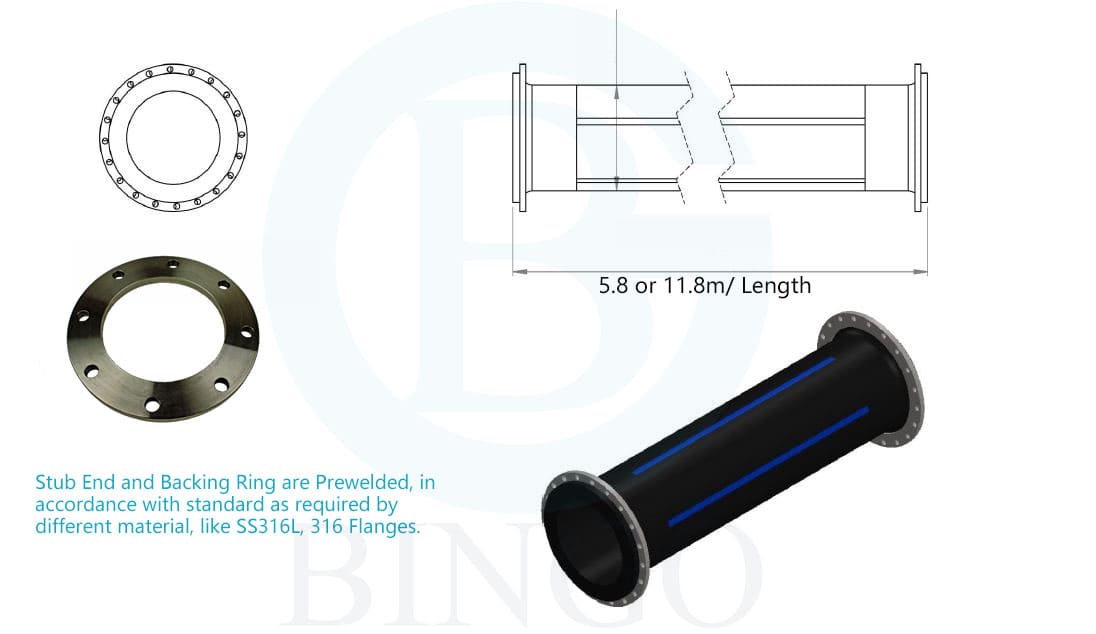

- 2.Packing: 11.8m/ Pcs for 40ft or 5.8m/ Pcs.

- 3.CO (Certificate of Origin): China, CO could be provided by free.

- 4.Products Inspection: Raw material, production process, delivery or third-party factory inspection.

- 5.MOQ: Trial Order or 1*20ft containers by mixed loading.

Quick Details of High Density Polyethylene (HDPE) Dredging Pipes and Fittings

| Products details information | |

| Product name | High Density Polyethylene (HDPE) Dredging Pipes |

| Brand | Bingo pipeline(Customer brand is available) |

| Dia Ranges | DN110-2000mm(4 inch-80 inch) |

| Raw material | PE100, PE80, PE4710, PE3608, PE100RC... |

| Application | dredge of mud, mining projects,chemical industry, Sewage engineering, HDPE pipe for Marine... |

| Color | Black with blue stripes, black or others colors |

| Standards | ISO 4427, EN12201, AS/NZS4130, ASTM 3035, DIN8074, GOST18599, ASTM F714... |

| Matching products | HDPE pipe fittings, Customized PE fittings, floaters, Rubber hose, DI/ Steel backing ring flanges, dredging mud pump, welding machines and tools, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50 years with normal use |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE... |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection |

| Service | Research, Design, manufacture, Test, Sales, Solution Providing, After-sale service |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of High Density Polyethylene (HDPE) Dredging Pipes and Fittings

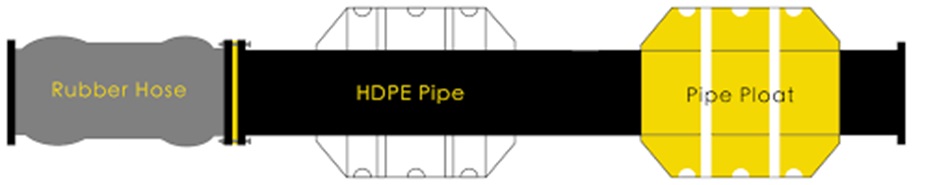

HDPE Dredging Pipes are made by High Density Polyethylene material(PE100) and has produced in various dimensions in order to use mostly on the sea to carry of sea sand for dredge of the mud. HDPE Dredger Pipes has manufactured and welded with the fittings as HDPE Flanged pipes or HDPE Two Flanged Pipes. The Dredging Pipes welded with two HDPE Flange Adapter and two Steel Flanges to be connect the pipes to each other and covered with Floaters – Floating Clamps to keep on the above sea. HDPE Dredging Pipes are easy to transport, installation, using of the pipes for all dredger or outfall projects. Dredger pipes are preferred for agricultural applications, dredge of mud, mining projects. Dredge Polyethylene Pipes are using together with floaters filled by Polyurethane (foam) material. Some projects need to use with Rubber hoses for the river or ocean dredger applications. For more applications HDPE Dredgers are can be apply safely due to high resistance and longlife of the HDPE piping material.

| HDPE Dredging Pipe with Accessories | ||

|

|

|

| Flanged HDPE Pipe | HDPE Floaters | Customized HDPE Pipe |

|

|

|

| HDPE Floaters 110-1200mm | Fabricated HDPE Flanged Bend | Rubber Hose for Dredging |

Advantages of High Density Polyethylene (HDPE) Dredging Pipes and Fittings

HDPE dredging pipes are usually produced with different diameter and thickness in 11.8m or 5.8 meter per length with stub ends and backing ring on both ends. It must be a pipe with welded flanges to the ends and some grooves inside and they specially design for dredging project.

Polyethylene Pipes have mechanical and chemical resistance. against hot and weather conditions. Another characteristic of PE pipes is ineffectiveness of sea salt and chemical material on them.

Dredge Pipes applicable easily because of the their lightweight speciality and buoyancy. The Dredger Pipes have various using area that applicable with big preferences.

Dredging HDPE pipes has long life time

HDPE Dredger Pipes has resistance of the internal and external impacts that Dredging pipes mostly used in the discharge of the mud and it having damages the pipes from the internal wherein impurities because.

Dredging pipes have the resistance of the corrosion

The HDPE Dredge Pipes has splinter proof and leak-proof

The assembling of the dredging pipes easy and fast because of lightweight

Absorption ratio is subdued of the HDPE Dredging pipes

Dredging PEHD Pipes are applicable on the all above water projects with safely

At the same time, Dredging PEHD Pipes are used with rubber hose, which has good flexibility and can resist strong wind and waves.

Specifications of High Density Polyethylene (HDPE) Dredging Pipes and Fittings

| ISO 4427 Pipe Series | S 3.2 | S 4 | S 5 | S 6,3 | S 8 | S 10 | S 12,5 | S 16 | PE100 | |||||||||

| ASTM F714 DR | DR 7.4 | DR 9 | DR 11 | DR 13.6 | DR 17 | DR 21 | DR 26 | DR 33 | ||||||||||

| Nominal Pressure PE 100 | PN = 25 bar | PN = 20 bar | PN = 16 bar | PN = 12,5 bar | PN = 10 bar | PN = 8 bar | PN = 6 bar | PN = 5 bar | ||||||||||

| Nominal Size DN (mm) | Equiv Size (in) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Min T.W. (mm) | Average ID (mm) | Nominal Size DN (mm) |

| 110 | 4.33 | 15.1 | 78.00 | 12.3 | 83.92 | 10.0 | 88.80 | 8.1 | 92.83 | 6.6 | 96.01 | 5.3 | 98.76 | 4.2 | 101.10 | 3.33 | 102.93 | 110 |

| 125 | 4.92 | 17.1 | 88.70 | 14.0 | 95.32 | 11.4 | 100.83 | 9.2 | 105.50 | 7.4 | 109.31 | 6.0 | 112.28 | 4.8 | 114.82 | 3.79 | 116.97 | 125 |

| 140 | 5.51 | 19.2 | 99.30 | 15.7 | 106.72 | 12.7 | 113.08 | 10.3 | 118.16 | 8.3 | 122.40 | 6.7 | 125.80 | 5.4 | 128.55 | 4.24 | 131.01 | 140 |

| 160 | 6.30 | 21.9 | 113.60 | 17.9 | 122.05 | 14.6 | 129.05 | 11.8 | 134.98 | 9.5 | 139.86 | 7.7 | 143.68 | 6.2 | 146.86 | 4.85 | 149.72 | 160 |

| 180 | 7.09 | 24.6 | 127.80 | 20.1 | 137.39 | 16.4 | 145.23 | 13.3 | 151.80 | 10.7 | 157.32 | 8.6 | 161.77 | 6.9 | 165.37 | 5.45 | 168.44 | 180 |

| 200 | 7.87 | 27.4 | 141.90 | 22.4 | 152.51 | 18.2 | 161.42 | 14.7 | 168.84 | 11.9 | 174.77 | 9.6 | 179.65 | 7.7 | 183.68 | 6.06 | 187.15 | 200 |

| 225 | 8.86 | 30.8 | 159.70 | 25.2 | 171.58 | 20.5 | 181.54 | 16.6 | 189.81 | 13.4 | 196.59 | 10.8 | 202.10 | 8.6 | 206.77 | 6.82 | 210.55 | 225 |

| 250 | 9.84 | 34.2 | 177.50 | 27.9 | 190.85 | 22.7 | 201.88 | 18.4 | 210.99 | 14.8 | 218.62 | 11.9 | 224.77 | 9.6 | 229.65 | 7.58 | 233.94 | 250 |

| 280 | 11.02 | 38.3 | 198.80 | 31.3 | 213.64 | 25.4 | 226.15 | 20.6 | 236.33 | 16.6 | 244.81 | 13.4 | 251.59 | 10.7 | 257.32 | 8.48 | 262.01 | 280 |

| 315 | 12.40 | 43.1 | 223.60 | 35.2 | 240.38 | 28.6 | 254.37 | 23.2 | 265.82 | 18.7 | 275.36 | 15.0 | 283.20 | 12.1 | 289.35 | 9.70 | 294.44 | 315 |

| 355 | 13.98 | 48.5 | 252.20 | 39.7 | 270.84 | 32.2 | 286.74 | 26.1 | 299.67 | 21.1 | 310.27 | 16.9 | 319.17 | 13.6 | 326.17 | 10.90 | 331.89 | 355 |

| 400 | 15.75 | 54.7 | 284.00 | 44.7 | 305.24 | 36.3 | 323.04 | 29.4 | 337.67 | 23.7 | 349.76 | 19.1 | 359.51 | 15.3 | 367.56 | 12.30 | 373.92 | 400 |

| 450 | 17.72 | 61.5 | 319.60 | 50.3 | 343.36 | 40.9 | 363.29 | 33.1 | 379.83 | 26.7 | 393.40 | 21.5 | 404.42 | 17.2 | 413.54 | 13.80 | 420.74 | 450 |

| 500 | 19.69 | 67.6 | 356.70 | 55.8 | 381.70 | 45.4 | 403.75 | 36.8 | 421.98 | 29.7 | 437.04 | 23.9 | 449.33 | 19.1 | 459.51 | 15.30 | 467.56 | 500 |

| 560 | 22.05 | 75.7 | 399.50 | 62.5 | 427.50 | 50.8 | 452.30 | 41.2 | 472.66 | 33.2 | 489.62 | 26.7 | 503.40 | 21.4 | 514.63 | 17.20 | 523.54 | 560 |

| 630 | 24.80 | 85.1 | 449.60 | 70.3 | 480.96 | 57.2 | 508.74 | 46.3 | 531.84 | 37.4 | 550.71 | 30.0 | 566.40 | 24.1 | 578.91 | 19.30 | 589.08 | 630 |

| 710 | 27.95 | 95.9 | 506.70 | 79.3 | 541.88 | 64.5 | 573.26 | 52.2 | 599.34 | 42.1 | 620.75 | 33.9 | 638.13 | 27.2 | 652.34 | 21.80 | 663.78 | 710 |

| 800 | 31.50 | 89.3 | 610.68 | 72.6 | 646.09 | 58.8 | 675.34 | 47.4 | 699.51 | 38.1 | 719.23 | 30.6 | 735.13 | 24.50 | 748.06 | 800 | ||

| 900 | 35.43 | 81.7 | 726.80 | 66.2 | 759.66 | 53.3 | 787.00 | 42.9 | 809.05 | 34.4 | 827.07 | 27.60 | 841.49 | 900 | ||||

| 1000 | 39.37 | 90.2 | 808.78 | 72.5 | 846.30 | 59.3 | 874.28 | 47.7 | 898.88 | 38.2 | 919.02 | 30.60 | 935.13 | 1000 | ||||

| 1200 | 47.24 | 88.2 | 1013.02 | 67.9 | 1056.05 | 57.2 | 1078.74 | 45.9 | 1102.69 | 36.70 | 1122.20 | 1200 | ||||||

| 1400 | 55.12 | 102.9 | 1181.85 | 82.4 | 1225.31 | 66.7 | 1258.60 | 53.5 | 1286.58 | 42.90 | 1309.05 | 1400 | ||||||

| This product flyer is intended for reference purposes. It should not be used in place of the advice from a licensed Professional Engineer. Nominal pressure (PN) is based on C = 1,25 and an operating temperature of 20°C. Weight is calculated using DN and Minimum wall plus 6% for use in estimating fluid flow. Actual ID will vary. When designing components to fit the pipe ID, refer to pipe dimensions and tolerances in the applicable pipe manufacturing specification. To obtain pressure in psi, multiply bar by 14.5 (1 bar ≈ 14.5 psi). | ||||||||||||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Application of High Density Polyethylene (HDPE) Dredging Pipes and Fittings

- hdpe dredging pipes applicable above the sea to outfall of the mud

- hdpe dredging pipes used in dredger projects from the lake, ocean floaters hdpe

- dredger pipes uses on the mining projects

- dredging hdpe pipes usable for the chemical industry

- river discharge applications also preferred with hdpe dredging pipes

- dredge of the sea sand is also an area of usage of the hdpe dredging tubes

- dredging pipes applicable for outfall of the sea

- dredge pipes uses for the agricultural projects

- hdpe dredging pipes applying for marina projects

- dredging pipes uses on seafaring

|

|

| HDPE Pipes for Dredging | HDPE Pipes for Slurry Dredging |

|

|

| HDPE Pipes for Dredging Project | HDPE Pipes for Sand Dredger |

High Density Polyethylene (HDPE) Dredging Pipes and Fittings

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.

English

English Español

Español