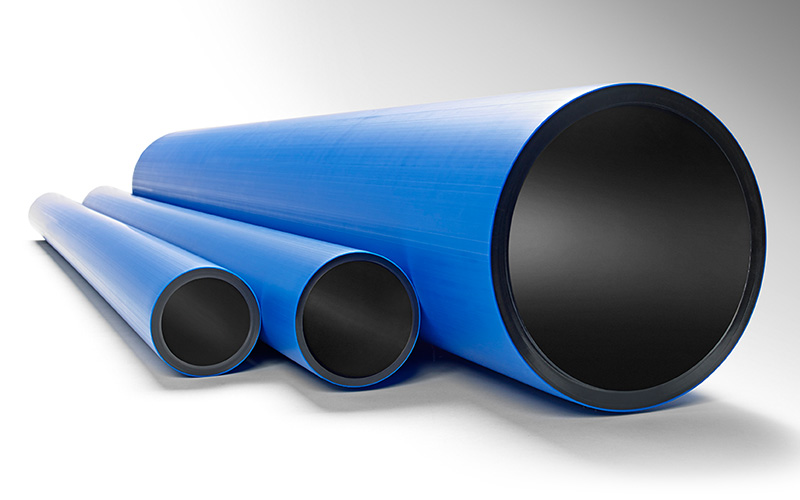

PE100RC is one of the highest-performance polyethylene materials for pressure piping systems. Known for its outstanding resistance to slow crack growth (SCG) and rapid crack propagation (RCP), it is extensively used in water supply, gas distribution, municipal infrastructure, and trenchless applications. Compared with standard PE100, PE100RC provides enhanced safety, durability, and construction flexibility.

PE100RC (Resistance to Crack) is an upgraded version of PE100, developed under EN 1555, EN 12201, and PAS 1075 standards. By optimizing its molecular structure, the material maintains excellent performance even under scratches, long-term loading, and harsh construction conditions.

Key features include:

High resistance to slow crack growth (SCG ≥ 8,760 h)

Superior rapid crack propagation resistance

Allows direct backfilling without sand bedding

Ideal for trenchless installation and pipe rehabilitation

PE100RC meets hygiene standards for potable water and prevents corrosion and metal leaching.

Ensures long-term stability under static loads and micro-damage environments.

Reduces construction costs and time, making it suitable for urban renewal and rural water supply systems.

Gas systems demand high safety, and PE100RC’s enhanced properties perfectly meet these requirements:

Minor installation damage does not compromise long-term integrity.

Prevents failures caused by ground movement, loading stress, or environmental factors.

Such as butt fusion, socket fusion, and electrofusion, making it ideal for new systems and network upgrades.

Municipal drinking water mains

Medium-pressure gas distribution

Industrial water and gas pipelines

Trenchless installation (HDD, pipe bursting)

Aging pipeline replacement

With superior durability, safety, and adaptability to complex installation environments, PE100RC has become the preferred material for modern water and gas engineering. It represents the future of long-life municipal and industrial piping systems.

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.