Choosing the right pipe material is critical for industrial and infrastructure projects. HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) pipes are two of the most widely used options. Each has distinct advantages depending on cost, lifespan, pressure requirements, and application environment.

PVC pipes generally have a lower initial purchase cost compared to HDPE pipes. This makes PVC attractive for budget-sensitive projects such as residential water supply and drainage.

However, HDPE pipes often provide lower lifecycle cost due to reduced maintenance, fewer joints, and longer service life. For large-scale or long-term industrial projects, HDPE is often more cost-effective over time.

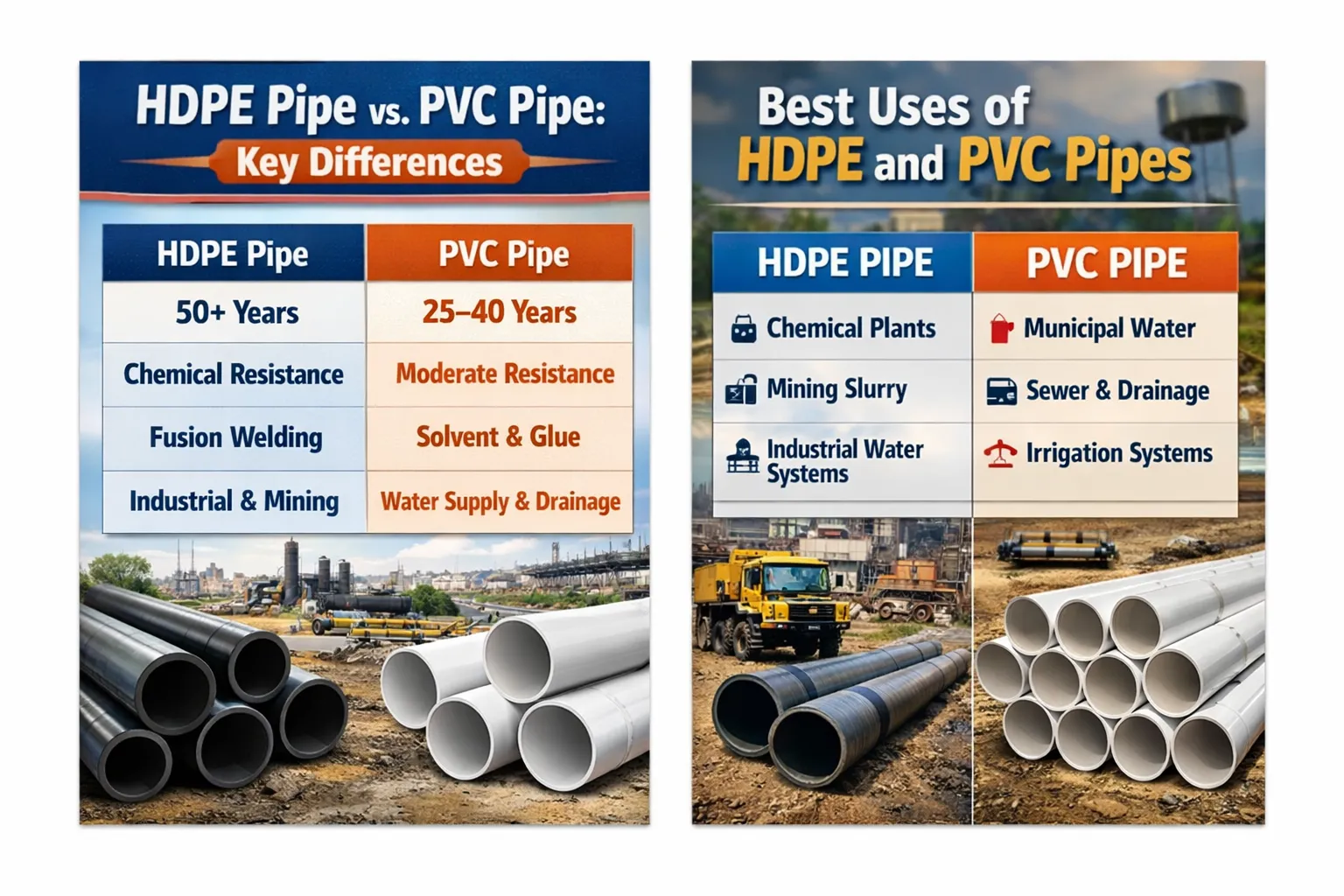

HDPE pipes typically have a service life of 50 years or more under normal operating conditions. They are resistant to corrosion, chemicals, abrasion, and ground movement.

PVC pipes have a service life of 25–40 years, depending on installation quality and environmental exposure. They are more rigid and may crack under impact or soil movement.

HDPE pipes are flexible and can withstand surge pressure and ground settlement. They are commonly used in high-pressure and trenchless installations.

PVC pipes offer good pressure performance but are more sensitive to temperature changes and mechanical stress.

HDPE Pipes are widely used in:

PVC Pipes are commonly used in:

If your project requires long service life, chemical resistance, and high reliability, HDPE pipes are the preferred choice. PVC pipes remain a cost-effective solution for standard, low-pressure applications. The final decision should consider operating conditions, installation method, and total lifecycle cost.

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.